Contact us

In specialized waste management companies, operators are often faced with the challenge of treating the collected industrial wastewater in such a way that all necessary official requirements are met. The large number of different types of wastewater and the pollutants it contains make this particularly difficult.

The limit values to be complied with are becoming increasingly strict and the demands on the waste disposal industry are rising. With our VACUDEST turnkey solutions solutions, which are specially adapted to your specialized waste management company, liquid waste can be processed without any problems.

In order to be able to react to your very individual wastewater needs we have developed the VACUDEST modular system. This modular system makes it possible to configure exactly the right treatment for your specific requirements.

Thanks to a thorough analysis of the wastewater produced in your company, it is possible to adapt the VACUDEST system with the right components exactly to your needs. YOUR ADVANTAGE: Profit from our many years of experience in the industry. This helps us to optimally plan the complete solution, guaranteeing flexibility in the face of changing wastewater compositions.

Reduce the amount of residue and save money in subsequent processes.

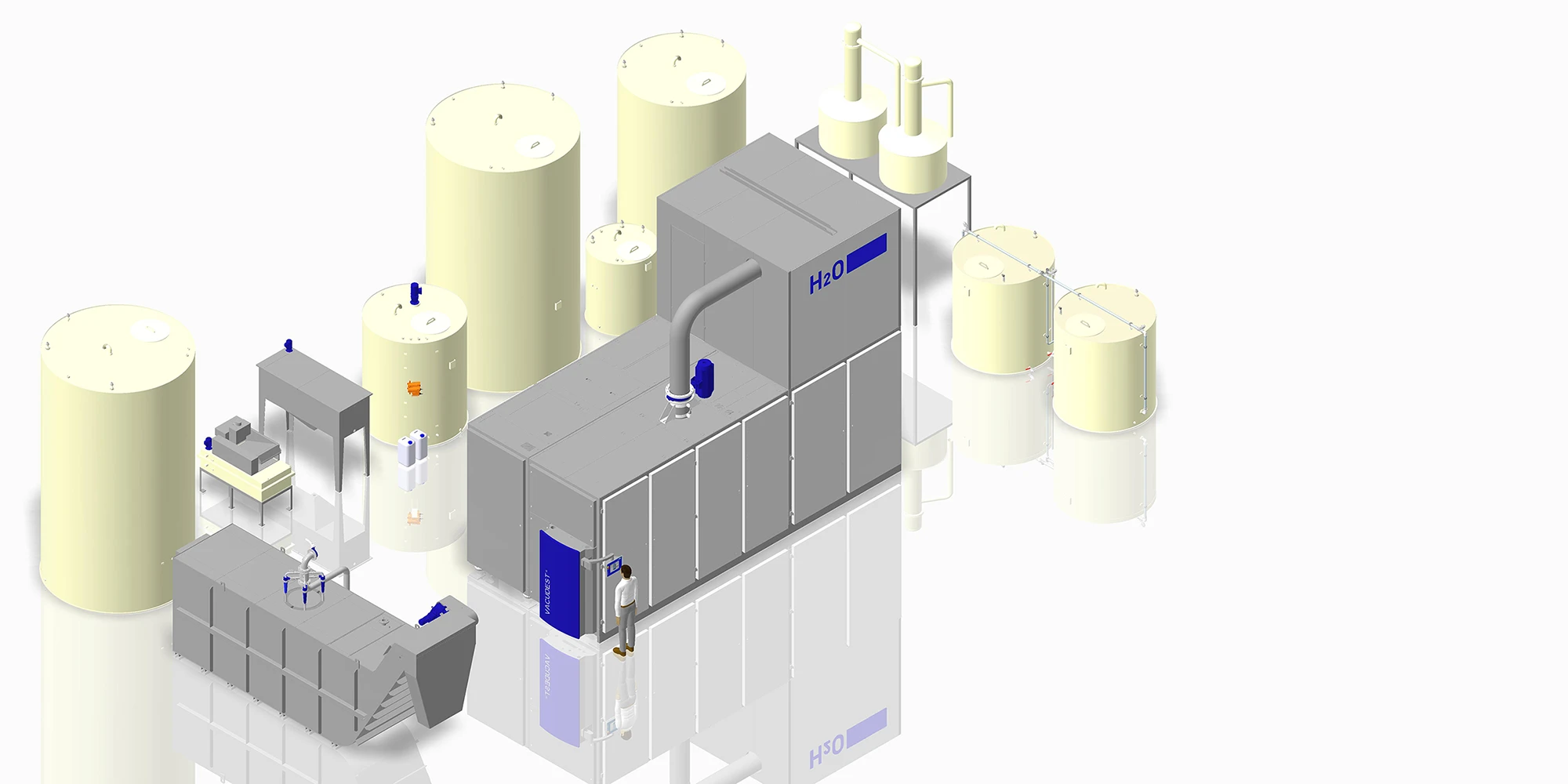

Based on the specific nature of your wastewater, our experts will design the unique treatment system required by you. A very comprehensive solution, as shown above, can, in addition to the various collection tanks for wastewater and distillate, include several other components for pre- and post-treatment. By means of scraper conveyors, belt filters as well as three-phase separators and neutralisation, the collected process water is optimally pre-treated to achieve the best possible result during vacuum distillation. A final distillate inspection serves as a quality check and gives you security when discharging your wastewater into the sewer.

The heart of the treatment process is our innovative VACUDEST vacuum evaporator - this example shows a machine capable of treating up to 8,000,000 gallons per year. Here we offer you the possibility to choose from further technologies, matched to your process water. Our patented Clearcat technology as well as the Purecat module, Destcontrol and Activepowerclean ensure you incomparable distillate quality and high process reliability in your plant.

Would you like to find out which solution is right for you? Contact our experts and let them advise you on your wastewater treatment.

For more advantages of the VACUDEST vacuum distillation units please follow the link.

Marius Straub

Sales Engineer

Phone: +49 173 2334982

marius.straub@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You can find our data sheets and brochures here ...

VACUDEST distillation units are ideal for treating industrial wastewater. They can be used in a wide range of industrial applications and can be scaled to suit any capacity thanks to a variety of sizes.

Your advantages

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com