Contact us

We are continuously working on the further development of our products and on innovative solutions for your sustainable production processes. Our innovation planning is strictly aligned with our vision of wastewater-free production. New in our portfolio is the VACUDEST ZLD technology. With the help of our VACUDEST ZLD concentrator it is possible to significantly improve the result of vacuum distillation with VACUDEST once again.

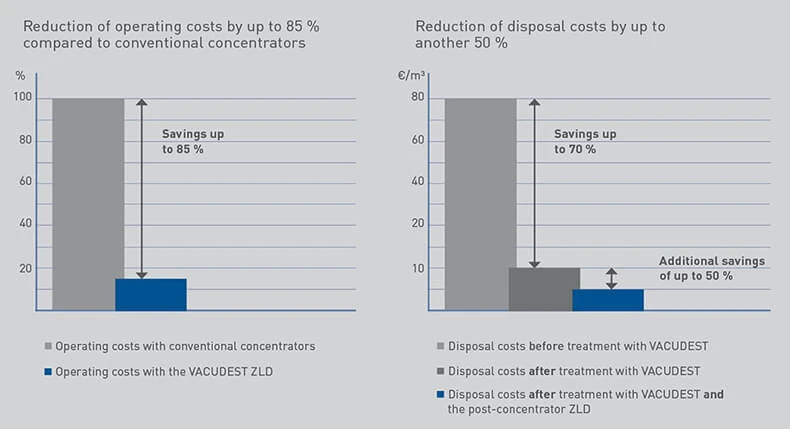

With our VACUDEST vacuum evaporators, customers from over 50 countries are already taking an important step towards wastewater-free production. By using our evaporator technology, our customers already reduce the amount of wastewater produced by up to 95% and the disposal costs by up to 70%. On the one hand, this reduces your costs and on the other hand, you make an important contribution to a sustainable environment.

However, the remaining residual water content of the residue can make complete disposal difficult. To avoid this, the post-concentrator VACUDEST ZLD is installed after the wastewater treatment with our VACUDEST vacuum evaporators.

Large amounts of energy are required for a downstream volume reduction due to high intermolecular interactions. Due to the salts and emulsified oils dissolved in the water, the vapour pressure is reduced during the concentration process, which is associated with an increase in the boiling point. A further difficulty lies in the increasingly lower heat transfer rates, which means that large surfaces are required for heat transfer. Here, the VACUDEST ZLD technology offers the solution.

In order to generate the required energy, technologies with large electrical energy consumers are often required and can be subject to strict legal regulations. This is where the VACUDEST ZLD technology is convincing.

Through efficient energy recycling, high-quality energy is used in a second downstream evaporation stage to achieve reductions in the residual water content of up to 20%. The energy-efficient system enables users to save up to 85 %* operating costs. This concept also enables enormous savings in disposal costs, namely by up to another 50%.

In addition, residues often contain valuable raw materials in the form of oils or dissolved salts, whose reuse offers additional economic potential. Because in such a case, the concentrate obtained can be sold, for example in the form of auxiliary fuels, or reused in our own production.

Reduce your operating and disposal costs to a minimum and save valuable fresh water resources at the same time

* compared to conventional concentrators

During concentration, encrustations on the heat exchanger surfaces can lead to considerable performance losses. This can be the case, for example, in saline applications. To prevent this case, we offer an optional mixer-system. The mixer, with specially developed scrapers, ensures free heat exchanger surfaces and keeps the already crystallized salt crystals in suspension to prevent deposits. Thus, the ZLD is permanently efficient and the maintenance effort remains low.

The VACUDEST ZLD post-concentrator combines sustainability and economy in your production process

Currently, our customers receive the VACUDEST ZLD technology for wastewater volumes between 2,100 and 16,000 m³/year. For the operation of the ZLD, the waste heat of the upstream VACUDEST is used, which significantly reduces the operating costs compared to other concentrators. The use of more than one post-concentrator is possible, so that the sizes VACUDEST M to XL can also be optimised with the help of the ZLD.

Do you have questions? Feel free to contact our Leaders in Zero Liquid Discharge. They will be glad to help you!

H2O GmbH

Wiesenstrasse 32

79585 Steinen I Germany

Telefon: +49 7627 9239-0

E-Mail: info@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com