Contact us

Many metal and plastic parts that we encounter every day are painted. These parts are sealed and protected against external influences such as rust, weathering or sunlight. Usually, there is always a pre-treatment which consists of numerous pre-treatment processes due to the different parts to be painted. The parts must always be thoroughly cleaned to ensure that the painting has got a long shelf life and fulfils its purpose.

Rinsing water treatment is becoming increasingly important in paint pre-treatment and it has become an indispensable, quality-relevant production process in the recent years. For this reason, more and more companies are using vacuum distillation units for the recycling of rinsing water.

Whether iron phosphating, degreasing or nanoceramics – today vacuum distillation plants are the state of the art technology for the treatment and recycling of rinsing water from paint pretreatment. Depending on the processed material and desired corrosion protection of the intended workpieces to be painted, a special pretreatment process might be recommended. Once the process stages, chemistry and water quality requirements have been determined, a suitable treatment system can be planned. Not only the size and type of the evaporator are selected, but also the necessary components such as tanks, neutralization equipment, ion exchangers and reverse osmosis systems.

The goal of a process water technology is always a reliable and automatic system working: The paint pretreatment must not fail due to poor or fluctuating water quality in the circulation system.

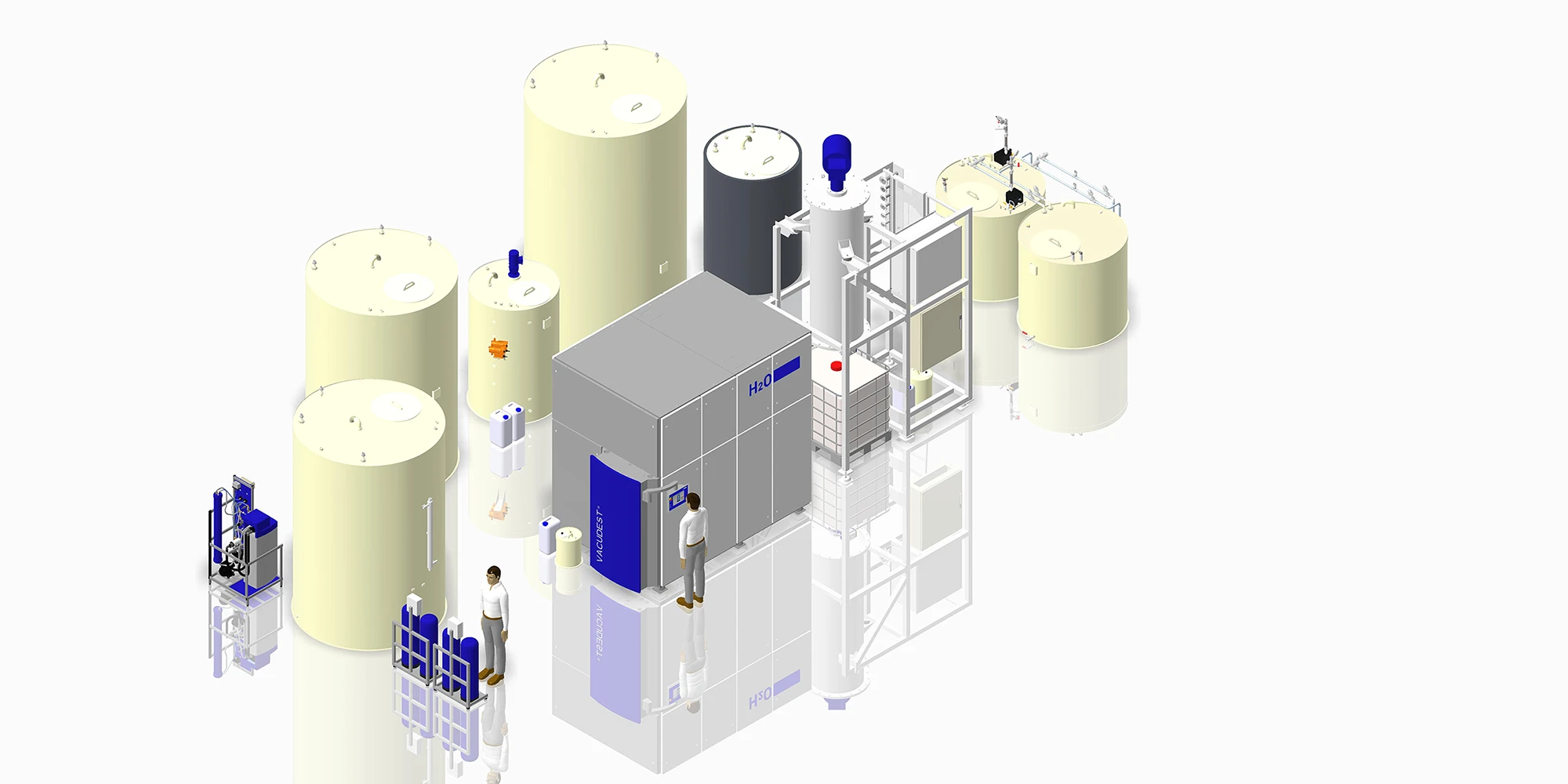

With the concept developed by H2O GmbH based on the latest technology, one obtains a very simple, flexible and modularly designed system, which is suitable for a variety of possible coating processes.

In our application centre for wastewater-free production, our experts have been continuously developing innovative technologies for over 30 years, which decisively improve the quality of the distillate. You can rely on our complete solutions, which are always individually adapted to the needs of your production.

In addition to the various containers that are explicitly provided for your process water, the VACUDEST vacuum evaporator (in this example a plant for up to 1,200,000 gallons per year) forms the heart of your complete solution. Equipped with our most important technologies, such as Clearcat, Destcontrol, Activepowerclean and the VacuCIP rinsing device, your system is prepared for the occuring wastewater. Thanks to our sophisticated system, you will receive crystal-clear distillate that reliably meets all quality requirements at a very good, constant level. These and many other technologies make our VACUDEST vacuum distillation systems unique on the market worldwide and guarantee you the highest quality in surface technology processes.

For further concentration, the use of our VACUDEST ZLD is recommended. The downstream evaporation stage allows a further reduction of the residual water content, which will again significantly reduce your disposal costs.

Additional post-treatment stages can make sense in individual cases. Therefore, we will be pleased to support you with an ion exchange, reverse osmosis, activated carbon or an UV treatment system.

Which components you finally need in your production depends strongly on the composition of the rinsing water. Contact our experts and together we will find the right solution for your production.

For more advantages of the VACUDEST vacuum distillation units please follow the link.

Thomas Dotterweich

Senior Sales Engineer

Phone: +49 172 7004047

thomas.dotterweich@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You can find our data sheets and brochures here ...

VACUDEST distillation units are ideal for treating industrial wastewater. They can be used in a wide range of industrial applications and can be scaled to suit any capacity thanks to a variety of sizes.

Your advantages

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com