Contact us

Currently, hardly anything is more present in chemistry than the discussions around the topic of PFAS and the pros and cons of a ban. Here you can read about what PFAS are, their benefits and their impact on nature and people. It also shows how efficiently and, above all, sustainably PFAS-containing process water can be treated using the vacuum distillation process.

PFAS stands for per- and polyfluorinated alkyl substances. Generally speaking, these are organofluorine compounds in which the hydrogen atoms have been partially (poly-) or completely (per-) replaced by fluorine atoms. It is estimated that the term PFAS now covers more than 10,000 synthetically produced chemicals, although so far only a fraction of these have really been adequately studied and their effects on humans, animals and the environment can be assessed.

Due to their properties, PFASs have found their way into many areas of everyday life in the past. They can be found in household products (e.g. in coatings of pans, raclettes, highlighters, various cosmetics or textiles, etc.) as well as in industrial plants (wetting agents in the paper industry or surface treatment, fire extinguishing agents). However, they also enter our waters via agriculturally used areas (plant protection products).

The problem with PFASs is their properties, which actually make them so useful. The compounds are extremely stable, so that neither biotic (e.g. bacteria in sewage treatment plants) nor abiotic processes (e.g. weathering) contribute to their degradation, and the PFASs thus accumulate in soils and waters for years and thus enter the food chain.

Since PFASs are now being detected in the most remote places on earth, legislators have also started to rethink their approach. Already at the beginning of 2021, the EU Drinking Water Ordinance came into force, which for the first time included two cumulative limit values for PFAS. With the amendment of the Drinking Water Ordinance, it was also translated into national law at the beginning of 2023.

But why not start at the source and treat wastewater containing PFAS reliably and efficiently and ideally recirculate it?

This not only minimises future impacts on humans and nature, but also conserves water resources.

Wastewater containing PFAS is diverse and usually a complex mixture of many inorganic and organic substances. These changing wastewater compositions pose great challenges to many classic treatment technologies, such as membrane or adsorption processes. However, treatment methods such as activated carbon, ion exchange, membrane/reverse osmosis or oxidative processes can be very suitable for selected applications. However, due to the great variability of PFAS, complete separation cannot always be guaranteed for every compound. Not so with vacuum distillation.

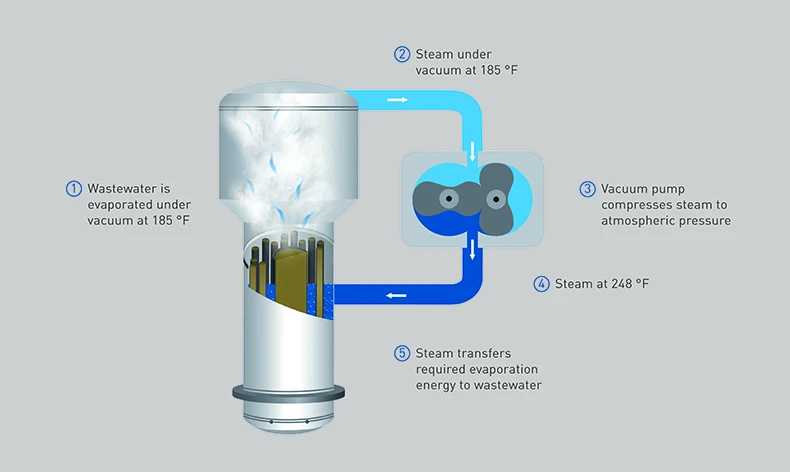

Vacuum distillation is based on the simple principle of separating substances according to boiling point differences - the industrial waste water is evaporated. All substances that have a higher boiling point than water remain in the evaporation residue.

VACUDEST or vacuum distillation is particularly suitable for heavily polluted waste water. The distillate obtained is not only PFAS-free, but also 100 % salt-free and can subsequently be reused. This is proven by a current example from the application centre for wastewater-free production at H2O GmbH: A reduction of PFAS of up to 99.99% has already been achieved in laboratory samples from a company that is one of the world's leading manufacturers of fluoropolymers.

Functional principle of vacuum distillation (Illustration H2O GmbH)

Wastewater containing PFASs is diverse and can vary greatly in composition. Due to the great variability of PFAS, complete separation by means of common treatment methods such as treatment with activated carbon, ion exchangers, membrane processes/reverse osmosis or oxidative processes cannot always be guaranteed for every compound.

However, this is guaranteed by treatment with the VACUDEST using vacuum distillation technology. In addition, waste water treated by the VACUDEST can be reused in the cycle for the most part, as it is also 100 % salt-free. Good for the wallet, but also very good for conserving fresh water resources.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com