Contact us

At Rabas Protec in Saint Nazaire, France, aluminium parts are produced, mainly for the aerospace industry. After mechanical processing, the parts are anodised and painted to protect them from corrosion. To do this, the surfaces of the parts are first prepared in degreasing baths, followed by sodium and acid pickling. Before the surface treatment, an NDT test can be carried out using dye penetrant testing. The final step is painting.

Rabas Protec is a subsidiary of the SOFIRA Group, whose activities are mainly focused on aviation. The group specialises in machining, surface treatment and painting of aluminium parts.

When parts are cleaned, rinsing water from the anodising process and the dye penetrant test accumulates. Until now, this water was treated by an aging vacuum evaporator with a theoretical treatment capacity of 15 cubic metres per day.

Due to the growing production, this capacity was no longer sufficient - therefore, investments were to be made in a more modern system. An important criterion was the quality of the treated water to be able to reuse it in the surface treatment sinks.

Vacuum distillation has established itself as the most economical solution for treating a wide variety of industrial wastewater. Especially when a high treatment quality is required, these systems offer an advantage over membrane systems or chemical-physical treatment methods, which leave a high level of residual contamination in the treated water. This is not the case with the energy-saving evaporation of wastewater under vacuum: the rising water vapour is free of contamination and can be reused - condensed as a clean distillate - in production processes.

Rabas Protec became aware of the VACUDEST vacuum distillation systems from H2O GmbH in Steinen, southern Germany, through internet research. "We were surprised by the promised quality of the distillate - we wanted to see it live."

A reference visit to the ammunition manufacturer Nexter in La Chapelle Saint Ursin followed. "During the on-site installation, we were particularly impressed by the cleanliness and automation of the operation," says Emmanuel Perdereau, Development & Investment Manager SAS SOFIRA at Rabas Protec. In addition, thanks to the good processing quality of the VACUDEST, Nexter was able to achieve scrap-free production without any post-treatment steps. "This is also what we wanted for our production."

The decision in favour of H2O and its VACUDEST was made primarily because of the high distillate quality, which had previously been confirmed in H2O's own laboratory in the application centre for wastewater-free production. This is made possible by innovative technologies such as the Clearcat condensation stage. With it, Rabas protec achieves an almost oil-free distillate. The COD - the value for organic pollution in the water - has been significantly improved.

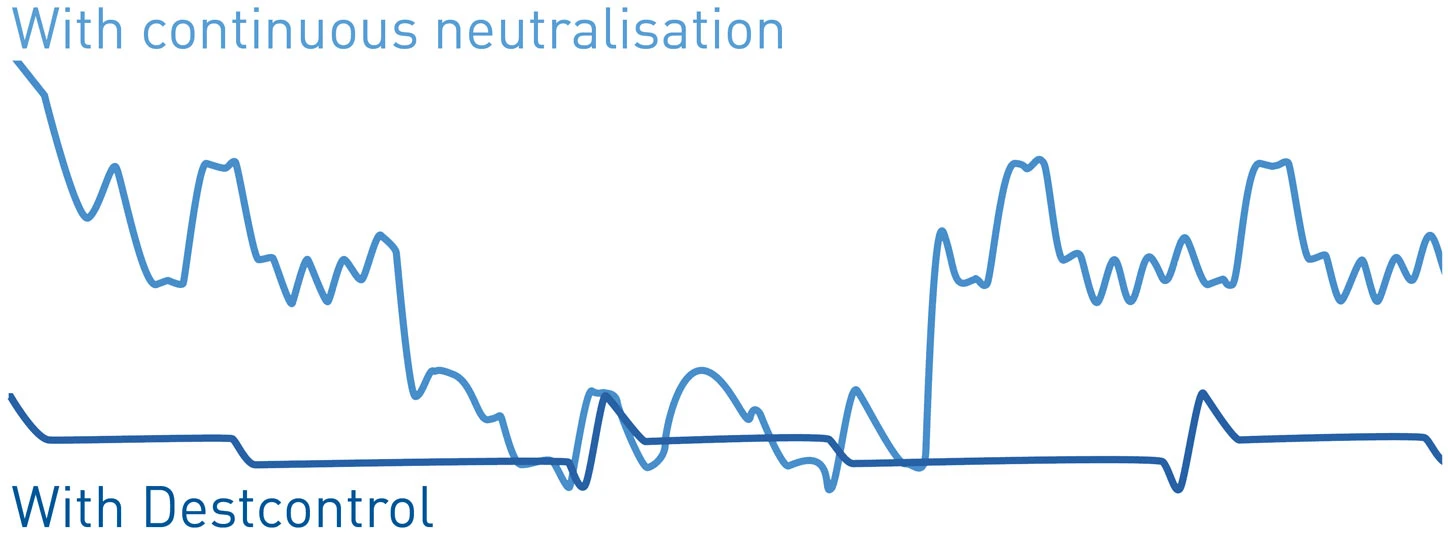

The conductivity value in the distillate was also a decisive argument in favour of the VACUDEST. By means of the Destcontrol technology, which can be integrated as a module into the VACUDEST system, the distillate achieves a stable pH value. Reactions that cause fluctuating pH values in the distillate with conventional evaporator systems are avoided.

This quality of the distillate gives Rabas protec more security for the production operation of its surface treatment plant. "We achieve savings in the operation and monitoring of our wastewater treatment," says Emmanuel Perdereau. The new wastewater treatment system also has other economic advantages: Energy consumption has decreased thanks to better energy recovery. The company is also happy about the time saved: "The operating costs are much lower because the system is fully automatic. And there are fewer checks and monitoring to optimise our means of production."

The H2O project management also received much praise from Rabas protec. It ensured the correct execution of the project within the schedule. Stéphane Guillotin, general director of SOFIRA, even wrote an email about it: "I would like to thank you for your professionalism and availability on behalf of the SOFIRA Group companies. We thank you for your commitment! It has become so rare that I wanted to write this to you."

Conclusion? Rabas Projet would choose H2O's systems again: "Such professional management deserves praise. All departments are extremely responsive and respond as accurately as possible to the needs of the customers. This is a service we want from all our suppliers and subcontractors. We can recommend H2O with full conviction. Because thanks to them, we can fully concentrate on our production."

“We can recommend H2O with full conviction. Because thanks to them, we can fully concentrate on our production."

Where other processes barely meet the legal discharge limits with a lot of additional equipment and operating effort, the Clearcat condensation stage is impressive in terms of the quality of the treated industrial wastewater. Even the strictest environmental standards are reliably met.

Comparison of pH value fluctuations in the distillate: Destcontrol reliably achieves stable values.

With Destcontrol, fluctuations in the pH value are a thing of the past. This innovative technology regulates the pH value in the purified distillate to the optimal value.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com