Contact us

Montblanc is a company based in Hamburg, Germany, that is well-known for manufacturing handcrafted, high-quality writing instruments. Perhaps the best known Montblanc product is the classic masterpiece, a fountain pen. The pen’s cap features the white star emblem, which is a stylised nod to Mont Blanc’s snowy peak. All Montblanc writing instruments are characterised by their high-quality materials. Many individual components in the pens – such as the nibs, rings and clips – are made from precious metals or are coated with precious metals. The metals used include gold, silver, platinum and palladium. An electroplating process is used to coat the components with these metals. This process results in wastewater that contains precious metals and that must be treated before it can be fed into the sewerage system.

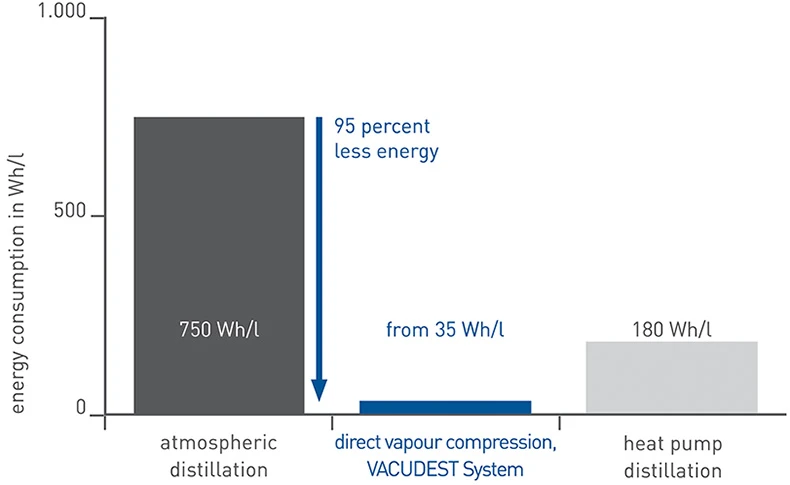

Previously, the wastewater was treated with an atmospheric evaporator in order to reduce the volume prior to being collected by a waste management company. Since this method of evaporation uses large quantities of energy and also leaves behind relatively large volumes of residue after the evaporation process, the company took the decision to look for alternative, more advanced technologies. The company not only aimed to reduce the processing costs but also to minimise the volume of waste in order to save residue disposal costs.

The vacuum distillation of H2O could quickly convince by their mature technology and especially by the low power consumption. The system evaporates the wastewater under vacuum and uses a clever energy return feature, which involves the energy of the steam being used to heat the wastewater that is flowing in. This then evaporates without the need for external heating. Compared to atmospheric evaporation, this represents an energy saving of 95 per cent.

“We have recorded significant cost savings. Before, we had to pay the expensive disposal costs for 60 m³ each year – now it’s only 4 m³. It’s an enormous saving and the investment will soon pay for itself,” says Thomas Langer, Head of Electroplating.

Thanks to clever energy recycling, evaporating under vacuum delivers an energy saving of 95 per cent and therefore reduces energy costs by 95 per cent.

In order to determine the process parameters, the first step was to use a wastewater sample to carry out tests at H2O’s application centre for zero liquid discharge production. After this first step, it was already possible to ascertain the expected quantities of residue and the distillate quality that can be achieved. The quantity of residue as a proportion is an indicator of the disposal costs that will arise subsequently. It is important that the highest possible level of concentration can be reached with the evaporator at this stage to minimise the volume of residue that requires disposal. H2O’s results showed that the residue quantity only represented five per cent of the total volume.

Concerning the distillate quality, it was important to reach the local discharge limits because the aim was to release the distillate after processing.

All requirements in terms of economic viability and quality were successfully met, which resulted in Montblanc choosing a VACUDEST vacuum distillation system.

With the modern Vacutouch machine control the operation of the vacuum distillation unit is fully automated. It requires only minimal supervision, which is limited to a few control functions for the system operator. With this high level of automation, manual intervention and adaptation is avoided, which in turn increases the process security. Additionally, the fully automated process also significantly reduces the workload.

Thomas Langer, Head of Electroplating, is very happy with his decision. “The vacuum distillation system vastly reduces the workload because its functions are fully automated. Previously, the amount of manual intervention was significant, because we had to make regular adaptations according to the process water.”

The vacuum distillation system used by the Electroplating division at Montblanc treats rinsing water that contains precious metals.

It also reduces costs for energy and disposal.

Author:

André Turkowski

Regional Sales Manager, H2O GmbH

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com