Contact us

Wastewater-free production - for a modern, sustainable company like Sony DADC, this was one of the most important requirements for a new wastewater treatment system for the enlarged production facility in Thalgau/Austria

Sony DADC opted for a VACUDEST vacuum distillation system: the plant runs automatically and is available around the clock without any major support effort. This is a decisive advantage over the previous chemical-physical waste water treatment.

Sony DADC Europe GmbH is one of the largest manufacturers of optical storage media, such as CDs, DVDs, BluRays and much more

The decisive factor for us was that the system operates automatically and non-stop without any major manual support effort.

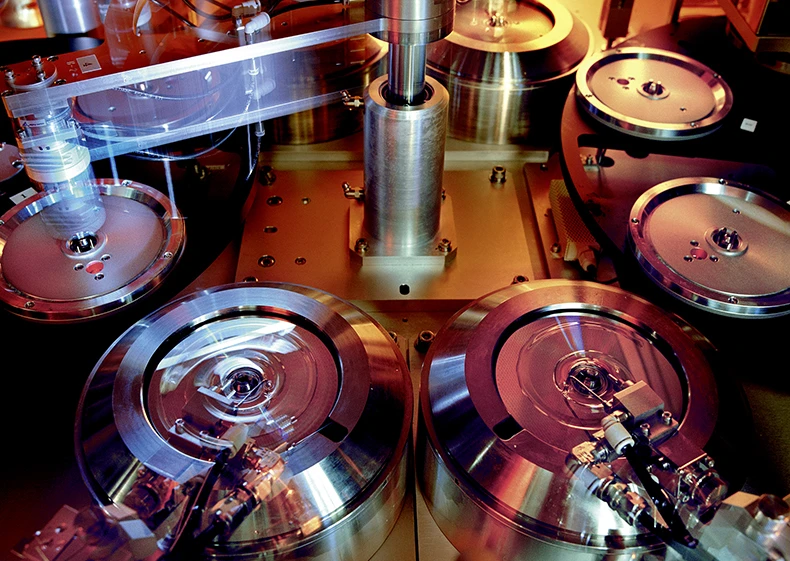

The production of optical data carriers - such as CD, DVD or BluRay, is an injection moulding process followed by a metallisation process (sputtering process with aluminium) and protective lacquering. This replication of the discs is highly automated with cycle times in the range of seconds.

At the end of the production steps in the clean room, the label printing - often colourful and very artistic artwork - is applied. The discs are then packaged in the assembly area. From there, the finished packaged products are shipped to the various countries via the logistics department.

The template required for injection moulding is produced by a lithographic electroforming (LiGA) process in the Mastering department.

This process produces waste water contaminated with nickel, caustic soda and other alkaline cleaning media, among other things. Further waste water is produced during replication. Maskings are used in the metallisation processes, some of which are chemically cleaned. Aluminum-containing, alkaline rinse water is produced in the process.

Until now, the waste water from these processes was treated by a chemical-physical plant.

During the production of the injection moulding matrices for the optical data carriers, rinsing water from the electroplating and cleaning of the injection moulding matrices is produced. The waste water, contaminated with nickel, caustic soda and nitric acid, among other things, is now sustainably treated and reused. (Photo: Sony DADC Europe GmbH)

In the course of merging the Anif and Thalgau plants, Sony took the opportunity to build a wastewater plant suitable for electroplating wastewater, as well as to construct a new plant for chemical mask cleaning. "In the course of these investments, we implemented numerous process improvements that made the use of vacuum distillation possible," Paul Weitnauer, Manager Mastering Engineering at Sony DADC, tells us. "In addition, we evaluated the advantages and disadvantages of the different systems."

Sony's requirement for wastewater treatment: a circulation of the distillate with a conductivity limit of < 20 μS/cm. The solution: the VACUDEST M 1.500 vacuum distillation system with conductivity monitoring. The treated water is 100 % reused in the process

Sony found that vacuum distillation enables the recycling of electroplating wastewater. All hazardous components can be separated and disposed of externally. This eliminates the possibility of the hazardous components passing into the municipal wastewater. "This made it much easier for us to get approval from the authorities to set up an electroplating department at the Thalgau plant," Weitnauer recalls. The treated water from the VACUDEST is further treated in an ion exchanger before further use and used in electroplating with a target conductivity value < 1 µS/cm.

Another decision criterion for vacuum distillation was the saving of valuable fresh water resources. "This helps us to guarantee our self-imposed goal of sustainable production of high-tech products in Austria," says the Manager Mastering Engineering proudly.

The compact VACUDEST vacuum distillation system was a big plus for Sony, as space is very limited at the Thalgau plant. Nevertheless, bringing the system into the basement of the production site was a highlight for everyone involved in the project, as the corridor was only 5 cm wider than the VACUDEST itself. "The meticulous preparation of the insertion helped a lot here - it quickly made us realise that we had some preliminary work to be done by construction companies, such as enlarging fire doors."

Conventional heat exchangers get dirty quickly: this means less performance with high energy consumption. An Activepowerclean heat exchanger stays clean thanks to circulating ceramic balls. For optimum system availability and higher energy efficiency.

The decisive factor for Sony was that the system is automatic and available around the clock without a great deal of supervision. This is where the VACUDEST has an advantage over physical-chemical precipitation. The system requires only a few hours of maintenance per week, which guarantees optimum system availability. "In the past peak season - the Christmas business is of great importance to us - the system made a valuable contribution," Weitnauer sums up.

The project was realised to the complete satisfaction of all parties involved, thus paving the way for further long-lasting and successful cooperation.

"Definitely worth a look is also the new VACUDEST ZLD to minimise the residual volume to be disposed of."

Paul Weitnauer, Manager Mastering Engineering at Sony DADC

The ZLD post-concentrator saves a further 50% in disposal costs thanks to its subsequent concentration.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com