Contact us

IWIS is one of the world's leading companies in their field of expertise and is regarded as a technology leader for high-quality chain drive systems for automotive and industrial applications. The engine systems division specializes in control, camshaft, mass balancing and oil pump drives for the automotive industry.

In the course of the expansion of production at IWIS in Landsberg and the acquisition of new parts washing systems, project manager Henning Fritz and the person responsible for the parts washing systems also considered a new wastewater treatment system. Due to the good experiences with the company H2O GmbH at the location in Munich and a very successful, quality-improving test run in their own production, the decision to use a sustainable VACUDEST vacuum distillation system for this site as well was made.

For more than 100 years, the iwis Group has been moving the world: As an internationally active technology leader and manufacturer of precision chain systems and mechanical drive technology, we strive to move forward side by side with the automotive sector and industry. With connection and contact technology in perfect precision, we continue to lead the automotive sector towards the future in terms of e-mobility and autonomous driving.

At the Landsberg site, mainly timing chains and pinions are produced. After production, these are cleaned from production residues in large parts washing plants. This produces washing water contaminated with heavy metals, oils and cleaning lye’s, which must not be discharged into the sewage system but instead have to be disposed of at high cost. Due to the relatively small amounts of wastewater, this was the most economical solution for the company so far.

The expansion of production and a new parts washing plant however now caused the wastewater quantities and thus also the disposal costs to increase, which brought one treatment approach in particular into focus: the processing with a vacuum distillation system.

VACUDEST vacuum distillation systems are not only economically attractive starting from as low as 200 cubic meters of wastewater per year, but also sustainable in their use. This is because up to 97 percent clean distillate is produced from 100 percent of wastewater while only leaving 3 percent residue behind. Due to the savings in disposal costs, the investment in such a system usually pays for itself in less than 2 years. In addition, the purified water can be reused in the production, which saves fresh water and enables wastewater-free production. From these advantages now also IWIS in Landsberg is benefitting.

The VACUDEST vacuum distillation system was already known from the IWIS site in Munich, where they had already had good experience with its use in parts cleaning. In order to check whether the system was also suitable for their production in Landsberg, H2O GmbH, the supplier of the VACUDEST vacuum distillation systems, first carried out a laboratory analysis with wastewater samples from the process. It was investigated whether the required conductivity of less than 200 µS/cm and a pH value of < 9 could be achieved. In addition, the target was the reuse of the purified water as rinsing water for the parts washers. All this was confirmed by H2O GmbH: The realization of the wastewater-free production in Landsberg could be greenlit.

IWIS tested the quality of the distillate as a rinsing medium once more in practice after the prior evaluation with a VACUDEST demonstration unit. The results after 4 weeks in operation were very convincing: "Our parts are cleaned better than ever before," sums up Henning Fritz, project manager, responsible for the parts washing systems at IWIS Motorensysteme, and adds: "We would love to keep the VACUDEST demonstration system right here!"

Now a new VACUDEST XS with a treatment capacity of 300 cubic meters per year treats the used production wastewater at IWIS. The system is hereby equipped with the Aktivdest, which removes organic components such as floating and free oils from the distillate and thus lowers the COD value, a conductance probe for checking the conductance in the distillate, the innovative technology Destcontrol for pH value control and the e-Service. This modem enables remote access by the service department of H2O GmbH, so that in 40 percent of cases a service technician visit on site is unnecessary.

H2O GmbH carried out the planning and installation in close cooperation with the supplier of the new parts washing systems - this way, all requirements could be considered as a whole and solutions could be implemented easily and quickly. At IWIS, the contaminated wastewater is now treated from the first, most heavily contaminated sink. First, a collection tank with centrifuge separates the floating oils from the parts washing wastewater. Before it is fed into the VACUDEST vacuum distillation system for evaporation, the rinse water temperature in the receiver tank is lowered from 60 to 50 degrees Celsius by a cooling loop. After the treatment the purified water is then fed into the final rinse for cleaning of the produced parts. Here, the rinse water is reused through the various rinses in a closed loop over several years. IWIS Landsberg is now wastewater-free.

Even after 3 years of operation, IWIS is still completely satisfied: "The VACUDEST is running excellently!" The savings, both in fresh water and in wastewater disposal costs, are enormous. In addition, the VACUDEST keeps all quality promises: "Our parts are significantly cleaner and residue-free since cleaning with the distillate from the VACUDEST!"

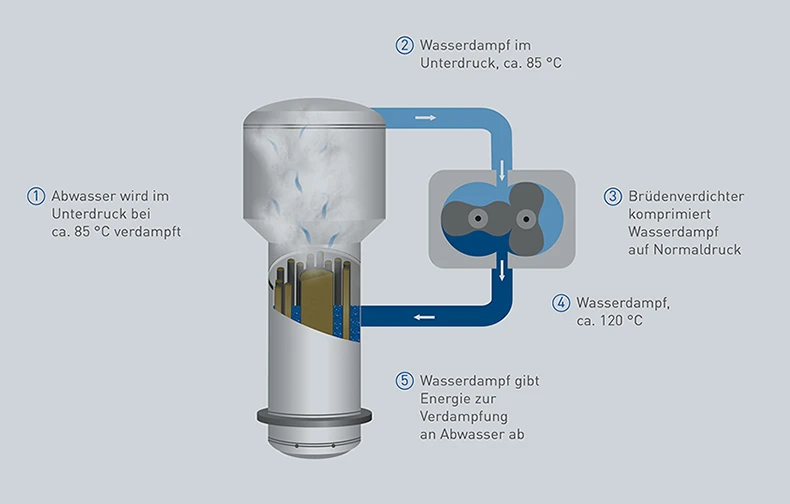

Vacuum distillation plants work on the simple principle of separating substances according to boiling point differences: The industrial wastewater is evaporated under a reduced pressure at a temperature of only about 80 degrees, instead of 100 degrees as at atmospheric pressure. All substances that have a higher boiling point than water remain in the evaporation residue. This includes heavy metals, salts, but also oils, fats or surfactants. Because the water content is evaporated, the volume of the residue from distillation is reduced to 0.5 to 5 per cent of the original wastewater volume. The rising steam, also called vapor, is almost free of impurities. After condensation, it can be returned to the production as clean process water.

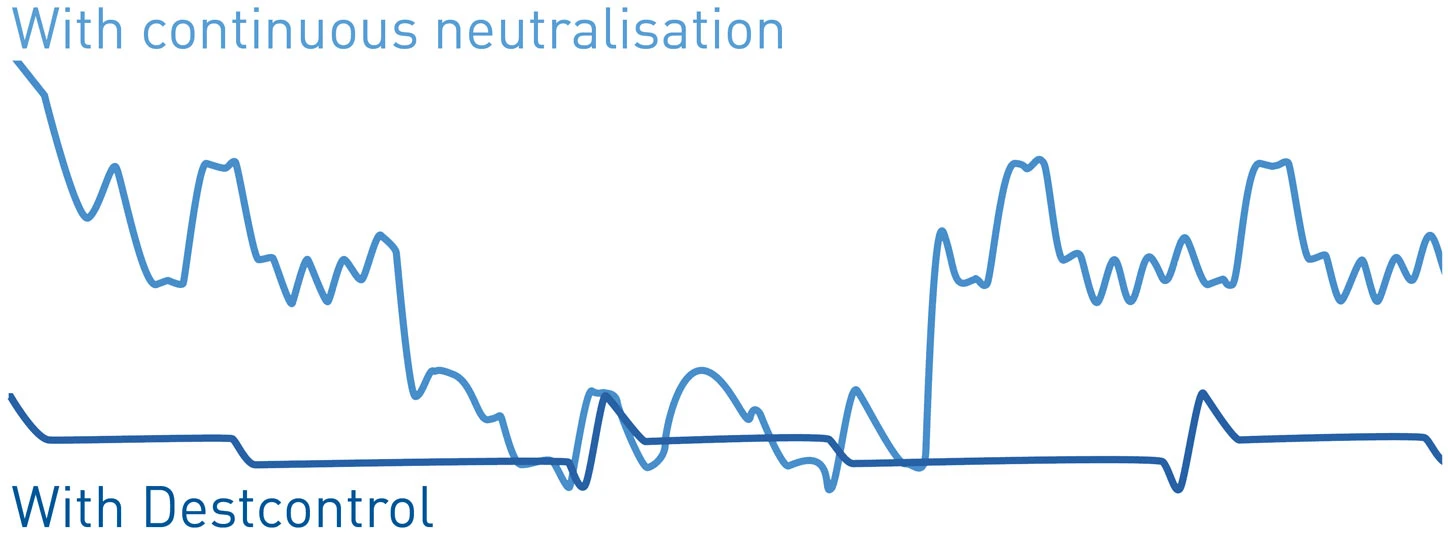

Comparison of pH value fluctuations in the distillate: Destcontrol reliably achieves stable values.

Conventional vacuum distillation systems adjust the pH value prior to the evaporation. The disadvantage is that after-reactions can be triggered during the evaporation process, which deteriorate the distillate quality. This is why H2O GmbH has developed the Destcontrol pH controller. With the Destcontrol control, the pH value is not measured in the feed, but in the purified distillate. If the pH values change here, neutralization agent is dosed directly into the VACUDEST evaporator for correction. Any after-reactions that occur are compensated for in this way. A constantly stable distillate quality is achieved.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com