Contact us

Less maintenance, better quality, more automation - that's what RDO Springs wanted to achieve with their new wastewater treatment. The decision was made in favour of an energy-saving VACUDEST system: "Now we can finally make better use of our resources!

RDO Springs in Bresles (60) designs, manufactures and markets billions of stainless steel or steel metal springs internationally. The company is one of the leading manufacturers in France.

Two types of products are manufactured at the RDO Springs site in Bresles:

Treatment of the wastewater was already done by evaporators using a competitor unit supplied three years ago. After storage, the distillate was returned for vibratory grinding and passivation.

The search for a solution to replace the existing evaporator involved several criteria:

Based on these decisive criteria, the experts for wastewater-free production at H2O GmbH took the following actions to find a solution:

The requirements were met by a VACUDEST 2.100 Clearcat evaporator, which can process up to 6 m³/day at a concentration factor of at least 33 or a maximum of 3 percent concentrate. RDO Springs opted for this vacuum evaporation solution and replaced the previous plant.

Operation and initial feedback

After more than a year of operation, the evaporator is delivering very satisfactory results. Mr. Sohier, production manager at RDO Springs, would make the decision for an H2O solution again and again: "The commissioning of the unit went very quick, and the training was comprehensive. We can now even reuse the distillate because the quality allows it. H2O's customer service is both competent and responsive. We are called back within an hour or at the latest within 24 hours. To refine the settings and stabilize the process, H2O sent an experienced technician on site for a week. In addition, the fully automated operation and easy maintenance of the machine allowed us to make better use of our resources and concentrate fully on production."

H2O's after-sales service now takes on the task of ensuring the machine's availability, answering questions, carrying out important maintenance work and recommending improvements where necessary.

H2O's customer service is both competent and responsive. We are called back within an hour or within 24 hours at the latest.“

Where other processes barely meet the legal discharge limits with a lot of additional equipment and operating effort, the Clearcat condensation stage is impressive in terms of the quality of the treated industrial wastewater. Even the strictest environmental standards are reliably met.

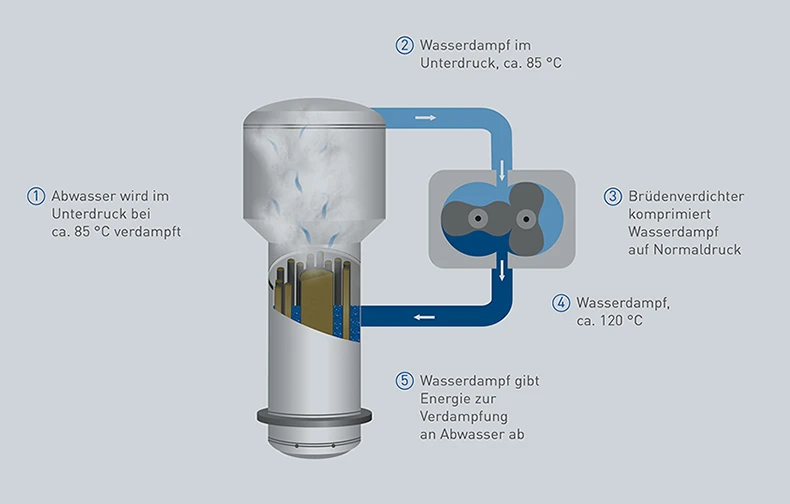

Vacuum evaporators are based on the simple principle of separating substances according to their boiling point differences. The industrial wastewater is evaporated. All substances that have a higher boiling point than water remain in the evaporation residue. This includes heavy metals, salts, oils, fats, or surfactants. Because the water content is evaporated, the residue is reduced to 0.5 to 5 percent of the original wastewater volume. The water vapor is virtually free of impurities. After its condensation, the clear water can be returned to the production process. This makes your production wastewater-free.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com