Contact us

Water is present in virtually every industrial process; it is not only used for manufacturing products, but also for diverse purposes accompanying the production process. These can be cleaning, processing, diluting, cooling, or transporting.

Water is essential in the production of almost any product, whether it is a car or a toothpick. A vast amount of water is spent in the production of paper, food, and chemicals. This so-called industrial water generated in production processes is usually contaminated after the production process and polluted with heavy metals, oils or salts among other substances of concern.

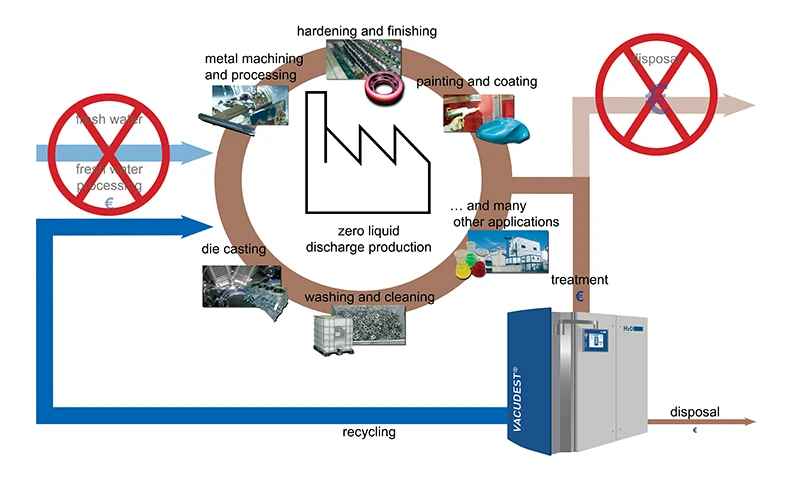

The contaminated water can cause severe environmental damage if it is returned to the public supply without being purified beforehand. Therefore, an efficient long-term strategy is to purify the contaminated water directly in the facility where it was produced, since the contamination usually makes up only a small fraction of about 2-3% of the wastewater and the purified water can be reused directly in the facility as well.

A vacuum distillation plant is perfectly suited for this purpose as it is highly energy-saving in comparison to atmospheric evaporation.

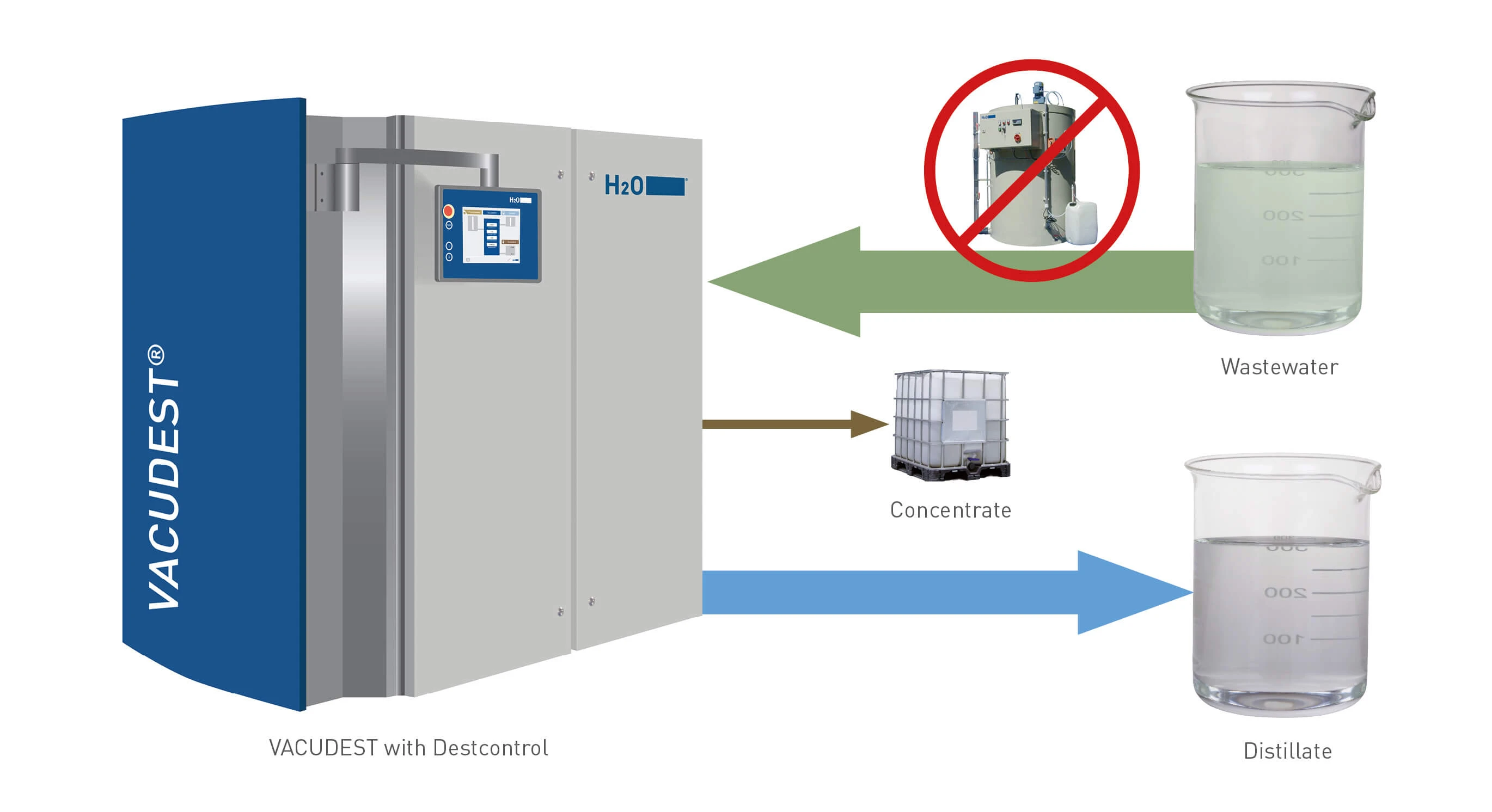

Vacuum distillation explained simply: The wastewater is evaporated, the dirt remains behind, the rising steam is free of impurities. The condensate, also called distillate, can be reused in production. In this way, 100 % waste water produces around 98 % cleag an water and only 2 % residue, which can be disposed of at minimal cost. The underlying physical principle is termed separation of substances according to boiling point differences.

This vacuum distillation method also saves energy, because water evaporates under vacuum at 80 degrees Celsius instead of 100 degrees Celsius. This has a major impact on the amount of energy consumed. Due to the use of heat exchangers and the reuse of the evaporation heat in the system, the set-up of a vacuum distillation consumes comparably little electricity. You can find another article about cost efficiency here.

Evaporation is a very obvious phenomenon, as it can be observed very easily in nature and also in the household, e.g.,salt is left behind when salty water like seawater evaporates. The evaporated water falls back to earth as clean, salt-free rain. Another example from the household would be the water vapor that collects as condensate on the lid of the pot. The condensate is pure water and does not contain any salt present in the pasta water.

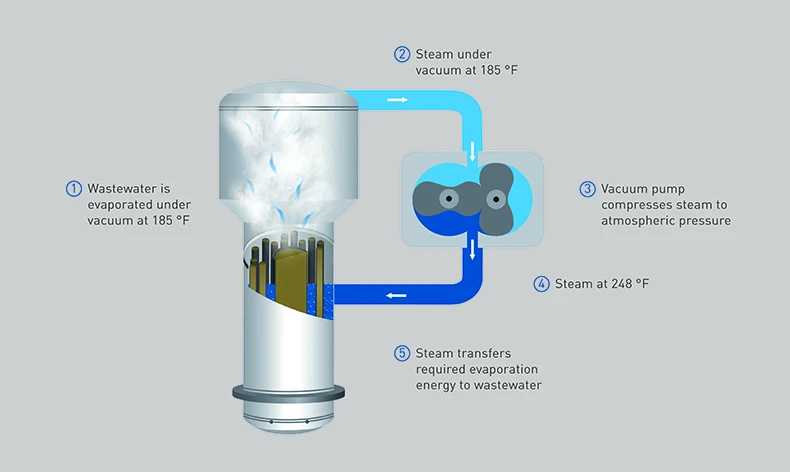

Part of the vacuum distillation process is called vacuum evaporation. Vacuum evaporation is a process in which a liquid is made to evaporate at a lower temperature than normal. The vacuum distillation principle is to lower the atmospheric pressure in a vessel containing the liquid below the vapor pressure of the liquid. This process can be applied to any liquid. However, the process of vacuum evaporation is usually associated with the effect where water can be brought to a boil at normal room temperature. An advantage of the method is that also energy of compression can be used for the evaporation (mechanical vapor recompression) and that no external energy is required for the condensation.

But probably the most important advantage of vacuum evaporation is the unspecific separation based exclusively on boiling points, which means that extremely diverse chemicals can be separated very effectively; the range covers for example heavy metals, salts, but also organic compounds like oils and fat. Vacuum evaporation can also be used to prevent the breakdown of liquids that should not be exposed to high temperatures.

Short path vacuum distillation is a very energy-saving technique for removing impurities from industrial wastewater. Since dirty water usually consists of only 2-3% or less of contaminants, vacuum distillation produces 98% pure water that can be returned to the production cycle.

This not only saves costs in the supply of new water for production, but also mitigates the costs incurred for external disposal services to an extreme degree.

Find out more about the applications and benefits of industrial vacuum distillation.

In the vacuum distillation process, the industrial wastewater is fed into a heat exchanger and evaporated under vacuum. The heat exchanger consists of a bundle of tubes in which the wastewater is divided into smaller volumes to make it easier to evaporate. The applied vacuum lead then to a modification of the boiling point. This allows water to evaporate at around 185 degrees Fahrenheit (85 °C) instead of 212 degrees Fahrenheit (100 °C) under atmospheric pressure.

All substances with a higher boiling point than water remain in the evaporation residue. The resulting vapor is then fed into the vapor compressor. It creates compression heat, which heats up the steam to 248 degrees Fahrenheit (120 °C). From the vapor compressor, the compressed steam hits the tube bundle again where the cooler wastewater is fed, condensing on the outer wall of the tubes. As a result, the steam reverts to liquid clean water and can be discharged from the system or returned to the production process. The contaminated evaporation residue is then drained off.

The heart of the wastewater treatment system is the vacuum distillation unit. Depending on the nature of the wastewater contamination, pre-treatment and post-treatment may be necessary.

Pretreatment can include a belt filter (or inclined belt filter), which is used to remove floatable and filterable solids from the water by means of a filter fleece selected to match the solids concentration and viscosity of the wastewater to be treated.

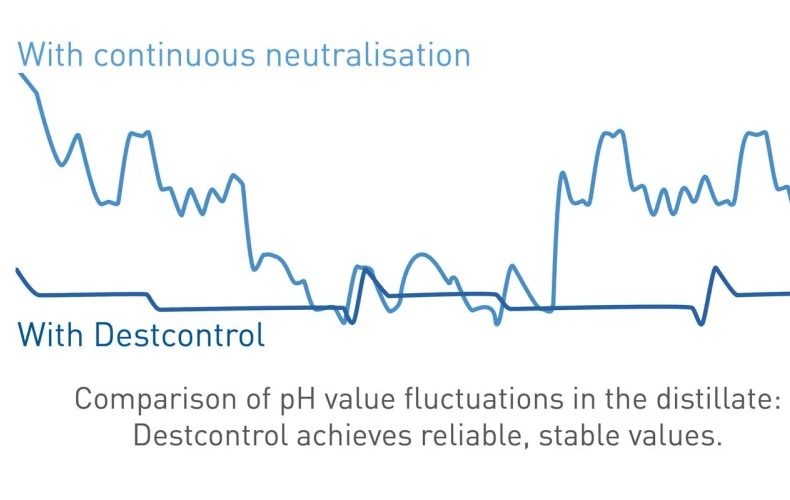

Pretreatment by a neutralization plant protects the microorganisms that break down organic substances in the wastewater, e.g., in the biological stage of a wastewater treatment plant. Microorganisms react very strongly to fluctuations in the pH value.

In a neutralization plant, substances such as hydrochloric acid or caustic soda are often used to produce a neutral liquid with a pH of 7 corresponding to that of water.

In the aftertreatment, ultrafiltration can be used. In this process, the pores of the semipermeable membrane (which can only be penetrated on one side) are smaller than in microfiltration, but larger than in nanofiltration.

In ultrafiltration, the treated dirty water is forced through plastic tubes at up to 10 bar resulting in particles, bacteria and viruses being collected in the pores of the filter tubes. The result is an absolutely germ-free water. The membranes are mainly made of very low-cost materials such as cellulose acetates or polyamides.

The H2O VACUDEST vacuum distillation system is very efficient and space-saving since technologies adapted to meet individual needs for improving water quality are already built into the machine ex works.

These are for example:

The H2O DESTCONTROL measures the pH value of the water not like conventional units in the feed, but instead in the purified distillate. The pH-value of industrial wastewater often differs drastically before and after evaporation as after-reactions can be triggered during the evaporation process.

The DESTCONTROL doses a neutralizing agent directly into the VACUDEST evaporator and thus compensates for any after-reactions that may occur. This not only ensures a constant distillate quality, but also makes an upstream continuous neutralization obsolete.

This additional option offers the possibility of treating industrial wastewater containing oil and grease in a single process step without additional manpower. The modules normally save an extra upstream oil separator.

In addition, this technology does not require any energy or auxiliary materials, as it is based on catalytic and physical effects. Clearcat and Purecat technology is seamlessly integrated into your vacuum distillation system and requires no additional space.

Clearcat technology lowers COD (Chemical Oxygen Demand) levels in wastewater to the point where they are 60% better than with other conventional vacuum distillation systems.

If you are aiming for recirculation in almost all industrial sectors, use the Purecat module in addition to the Clearcat. This can reduce the COD value by a further 50%.

Our VACUDEST vacuum distillation system already reduces the amount of wastewater by up to 95%. However, the remaining residual water content in the residues can sometimes make complete disposal difficult. This problem is eliminated by the VACUDEST ZLD post-concentrator.

In order to achieve a consistently high level of separation of the various substances during vacuum distillation and to ensure that the process is carried out reliably, it is important that the vacuum in the evaporator is sustained very precisely. Therefore, a high-quility pump is needed. In connection with vacuum distillation there are very many different pumping technologies in use. If you want to know more about them, please read the article Vacuum distillation pumps.

Vacuum distillation is not only a very environmentally friendly process due to the comparatively low energy consumption of evaporation, but also very economical, as one can see in this comparison to disposal of industrial wastewater.

Due to the recurring use of the water in the company's own production, very little water has to be sourced from new. However, the savings in disposal costs are the decisive factor, which means that a vacuum distillation plant usually amortizes after about two years.

Due to the low energy consumption, a vacuum distillation plant is also economically ahead of other water treatment technologies. In terms of fresh water costs, operating costs, and costs for the removal of evaporation residues and filter cakes, the vacuum distillation plant is ahead of other types of treatment such as chemical-physical treatment. Here you can find a comparison to alternative treatment methods.

International companies such as MAN and Audi rely on the H2O VACUDEST system on a daily basis, as it scores in areas such as surface technology, the metalworking and metal processing industries, as well as in waste disposal and aviation companies. The Clearcat and Purecat technologies also show their unique strengths when it comes to oily industrial wastewater.

To learn about the limitations of vacuum distillation, as well as our advice for the optimal wastewater solution, please read our article Application limits of vacuum distillation.

Vacuum distillation is not only used in industrial waste water treatment. It is also used in the production of alcoholic beverages, in the refining of petroleum and in laboratories.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com