Contact us

Highest requirements for component cleaning met:

The demands placed on components in the automotive industry are becoming more and more stringent - as a result, the requirements placed on manufacturers and suppliers in terms of cleanliness are also increasing. In order to increase this, H. u. E. Büschel GmbH invested in a modern VACUDEST vacuum distillation plant with "Clearcat" technology for the treatment of their used parts washing and vibratory finishing water. It also meets the highest requirements for the rinsing water quality. In addition to the existing VACUDEST S, the new plant will treat a higher water volume.

H. u. E. Büschel GmbH in Schwaig near Nuremberg in central Franconia develops, manufactures and processes fine-blanked parts for the automotive, electrical, and medical technology industries. Producing fine-blanked parts with homogeneous and smooth cut surfaces already in the stamping process minimizes the finishing efforts and saves costs. If post-processing is required due to special requirements for freedom from burrs or, for example, hardness, this is achieved with deburring and surface treatment processes. Various processes are available, such as fine grinding, belt grinding and vibratory grinding, as well as lapping and blasting. The removal of residues from vibratory grinding, residual dirt, grease from the components and washing prior to preservation places high demands on rinsing water quality and recirculation.

These processes currently produce 180 to 200 litres of rinsing water per hour, which would have to be disposed of. In order to reduce disposal costs and save fresh water, the used rinsing water has been treated with a VACUDEST vacuum distillation system since 2007. The treated water is crystal clear and of such a good quality that it is reused in the washing process as well as in the vibratory finishing application.

Sustainable thinking and acting are the basis for the long-term success of the company. Everyone has internalized this and all processes as well as procedures have been coordinated to function efficiently, in an environmentally friendly and energy-saving manner. Büschel sees it as its responsibility to protect the environment and to deal sustainably with the resources used.

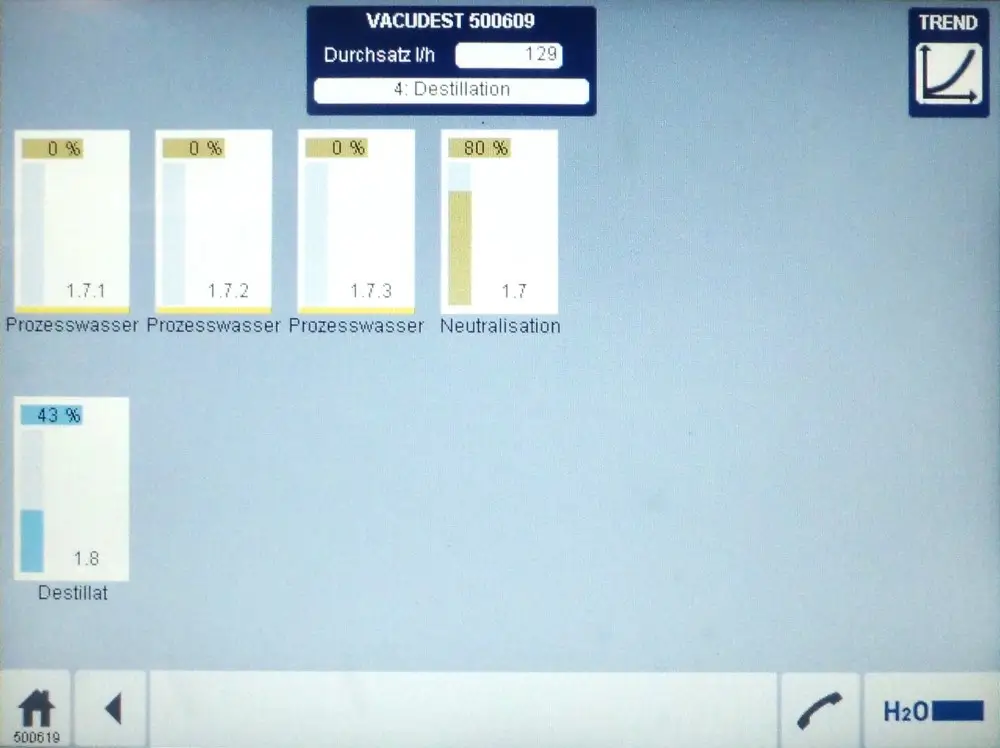

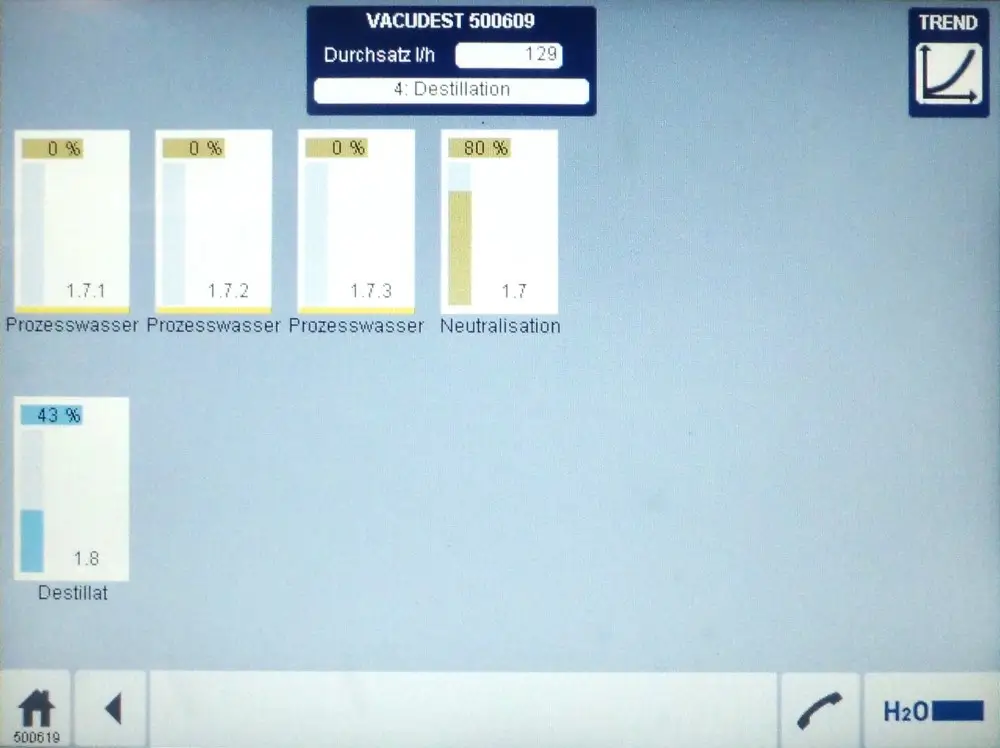

New demands on the cleanliness of the components and thus also on the rinsing water now made it necessary to use new washing and degreasing equipment. In order to cope with the growing orders and water volumes, the new system is supposed to have an additional treatment capacity of up to 125 litres per hour - i.e. double the current capacity of the existing VACUDEST S 750 CC. Likewise, both plants are using the existing tanks independently of each other.

"We were very satisfied with the existing model of our VACUDEST and with the service provided by H2O. The plant runs very reliably and trouble-free. Especially the APC works very well. We would like to build on this, and we will configure our new system with H2O again," says Andreas Wolf, manager of the vibratory finishing shop at H. u. E. Büschel GmbH.

The H2O analysis in the application centre for wastewater-free production resulted in the following equipment/modules

The new VACUDEST S 750 CC for H. u. E. Büschel GmbH was equipped with the following modules:

H2O met all the requirements for technology, treatment, and reuse of the distillate in the parts cleaning and vibratory finishing processes. Environmental requirements, such as the appropriate temperature of the distillate and a space-saving installation on a platform, were also met and confirmed.

Vacuum evaporators are based on the simple principle of separating substances according to their boiling point differences. The industrial wastewater is evaporated. All substances that have a higher boiling point than water remain in the evaporation residue. This includes heavy metals, salts, oils, fats, or surfactants. Because the water content is evaporated, the residue is reduced to 0.5 to 5 percent of the original wastewater volume. The water vapor is virtually free of impurities. After its condensation, the clear water can be returned to the production process. This makes your production wastewater-free.

Hydrocarbon reduction by the Clearcat technology is based on purely physical processes. No consumables or chemicals are required, which makes the Clearcat particularly economical and easy to maintain. A benefit that pays off: Whereas expensive activated carbon or high-maintenance residual oil separators were previously necessary, crystal-clear distillate with the lowest residual oil content now leaves the treatment plant. It’s up to the user whether the water is then discharged into the sewer or recirculated for a wastewater-free operation.

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com