Contact us

Industrial wastewater is often polluted with oil and fat, thus disposal into public sewer systems or open waters is not allowed. Instead, such waste water must be disposed of expensively with specialized waste management companies. Even for modern wastewater treatment systems processing of such wastewater is a challenge.

To reduce COD and oil index of industrial wastewater far enough, that it either can be recycled to the production process or be disposed of into the sewer system, requires mostly complex multi stage treatment processes. In our future oriented application center for zero liquid discharge production we continuously work on progressive solutions. This includes the patented Clearcat condensation system. This functional group for our state of the art VACUDEST vacuum distillation systems allows processing of oily industrial wastewater in a single process step, efficiently and reliably. The quality of the treated water sets benchmarks and fulfills even highest environmental standards. In the meantime more than 70 % of the VACUDEST vacuum distillation systems supplied are equipped with the proven Clearcat condensation system (US Patent No.: US 8,206,558 B2).

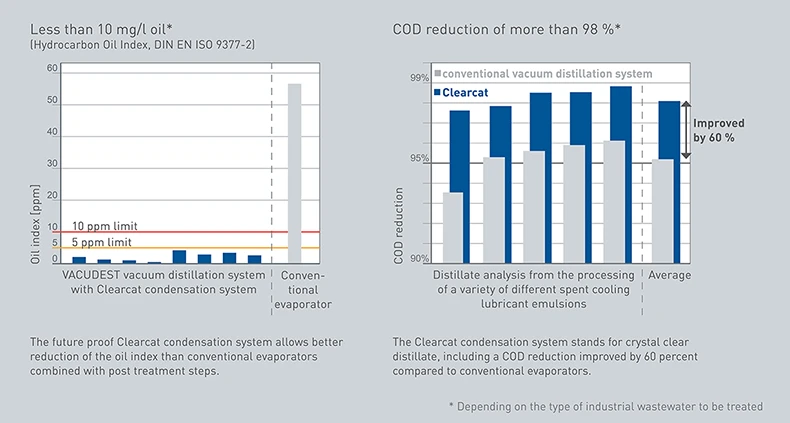

The future proof Clearcat condensation system allows better reduction of the oil index than conventional evaporators combined with post treatment steps.

The innovative Clearcat condensation system captivates by its efficiency. In a single process step oily industrial wastewaters are treated reliably without any additional operating efforts. That provides more time for important tasks.

The functional principle of the Clearcat condensation system is based on physical and catalytically effects, thus this state of the art technology neither requires additional energy nor auxiliary or operating materials. This allows you to improve the quality of the treated water without additional operating cost.

The Clearcat condensation system is integrated into the vacuum distillation system as a functional group from our VACUDEST Modular System. No space is required for additional post treatment of the distillate, thus you are saving valuable space for your production.

Other processes just reach the legal disposal limits based on additional equipment and processing steps, whereas the Clearcat condensation system sets benchmarks regarding quality of the treated water. Even highest environmental standards are kept. A valuable investment in a future worth living in.

* Depending on the type of industrial wastewater to be treated

H2O GmbH

Wiesenstrasse 32

79585 Steinen I Germany

Telefon: +49 7627 9239-0

E-Mail: info@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com