Contact us

The range of electronic devices is as diverse as the applications themselves, which leads to an equally large variance of process waters. For example, rinsing water from electroplating, vibratory grinding, industrial washing and cleaning water or even cooling lubricant and die-casting emulsions can be generated. Due to the different types of wastewater, treatment is usually difficult and disposal cost-intensive.

Limit values to be observed are becoming increasingly strict and the demands for the waste management industry are rising. Our many years of experience with a large number of different types of wastewater help us to find a solution that is specially tailored to customer needs, even if the composition of the wastewater is more complex.

The core of our complete solution is our VACUDEST vacuum evaporator technology. Based on our own wastewater analyses, we will put together an optimal system for wastewater treatment for you. This often allows the distillate obtained to be reused, which is a resource-saving and more cost-effective alternative to disposal.

In accordance with the large number of processes, the range of different process waters is equally large. In the following you will find a small selection of possible types of wastewater which H2O deals with.

The variety of different types of wastewater in the field of electronic equipment often poses a particular challenge for companies. With the help of our comprehensive VACUDEST wastewater treatment systems, you have the opportunity to treat your wastewater sustainably and cost-efficiently.

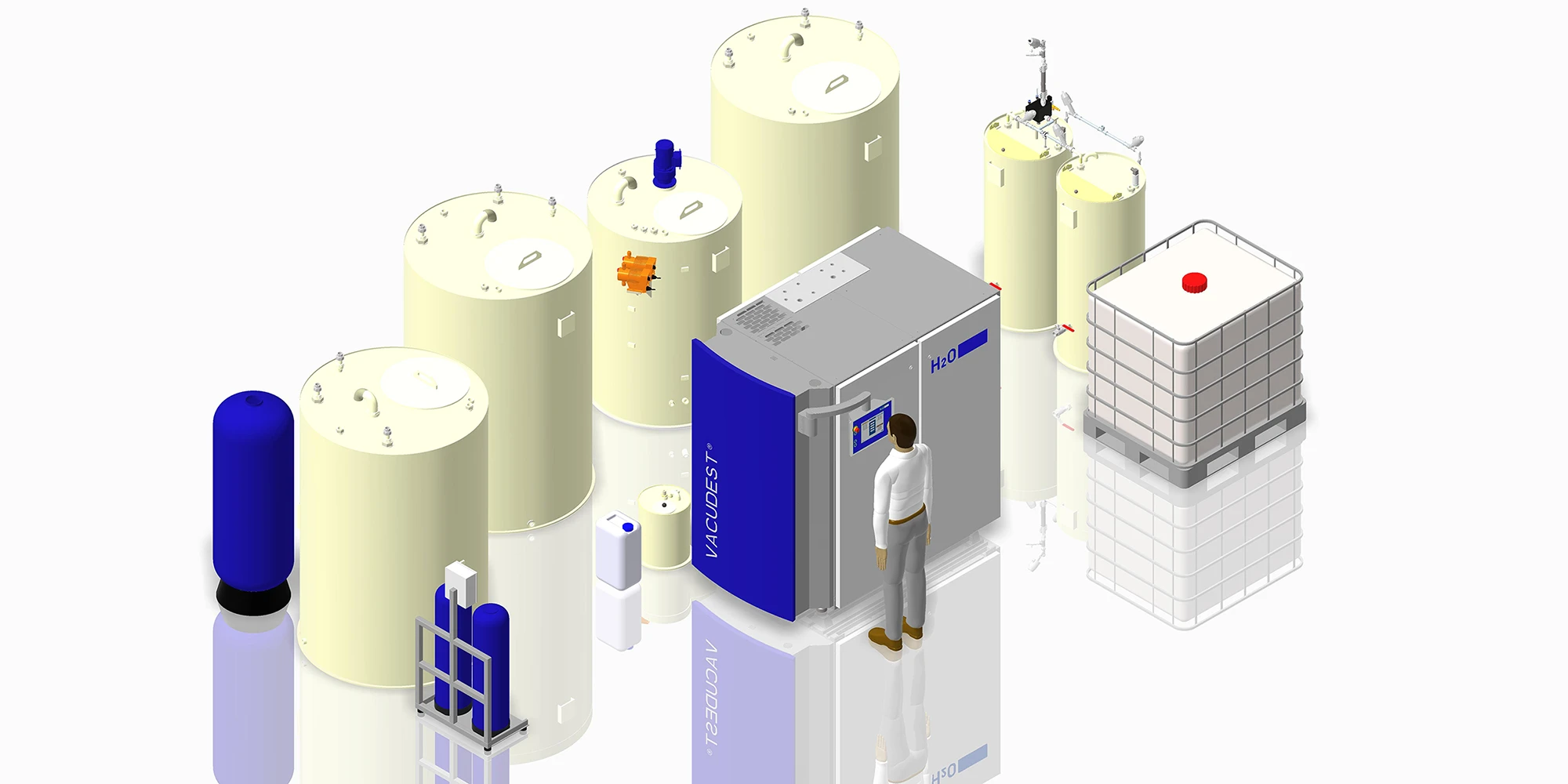

The VACUDEST vacuum evaporator forms the centre of the treatment. Shown here is a system for wastewater treatment for about 750 m³ / year. Your process water is collected in the tanks adapted to your process. In the sketched case study, the process water is checked again in a neutralisation device before entering the VACUDEST and, if necessary, adjusted to the optimum pH value. The wastewater is then fed into the VACUDEST and evaporated under vacuum. A simple solution could, for example, consist only of collection tanks and a VACUDEST. Depending on the ingredients in your process water and your requirements for the distillate, the addition of activated carbon, ion exchanger or UV treatment is recommended.

You can also benefit from our modular innovations such as Clearcat, Purecat, Destcontrol and Activepowerclean. These guarantee you consistently an optimal distillate quality and offer you a high level of process reliability.

For information on your individual treatment system, contact our experts and let them advise you.

For more advantages of the VACUDEST vacuum distillation units please follow the link.

Marius Straub

Sales Engineer

Phone: +49 173 2334982

marius.straub@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You can find our data sheets and brochures here ...

VACUDEST distillation units are ideal for treating industrial wastewater. They can be used in a wide range of industrial applications and can be scaled to suit any capacity thanks to a variety of sizes.

Your advantages

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com