Contact us

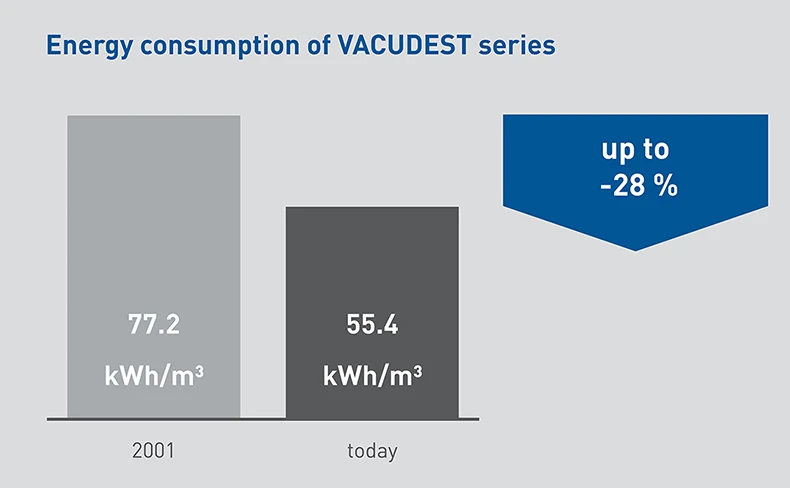

The Activepowerclean heat exchanger is one of the main reasons enabling us to reduce energy consumption of our VACUDEST wastewater evaporators by 28 % in recent years.

During evaporation of industrial wastewater the pollutants are concentrated in the heat exchanger of the evaporation system. This results in scaling on the inner heat exchanger surface and might even end up in blocking of the heat exchanger pipes.

Consequently system availability is reduced and extensive manual cleaning effort is necessary. In addition the scaling reduces efficiency of the evaporation system. Energy consumption is increased as well as the amount of evaporation residue.

The self-cleaning Activepowerclean heat exchanger reduces scaling and blocking of pipes already during the evaporation process. Inside the heat exchanger there are small ceramic balls, the so called Activepowerclean grinding balls. Due to high flow rates inside the heat exchanger pipes those grinding balls are circulated, reducing scaling reliably. Consequently operating efforts are reduced, since no extensive chemical and manual cleaning of the heat exchanger pipes is necessary.

Conventional wastewater evaporators get dirty quickly. This results in reduced capacity and higher energy consumption.

The self-cleaning Activepowerclean heat exchangers stays clean due to circulating grinding balls.

The Activepowerclean heat exchanger reduces scaling and prevents blocking of pipes reliably. This noticeably reduces cleaning efforts in between evaporation cycles. Consequently system availability is increased, operation efforts are reduced and consumption of rinsing chemicals is halved.

Scaling reduces heat transfer due to its insulating characteristics and therefore reduces energy efficiency. The Activepowerclean heat exchanger improves heat transfer noticeably, resulting in constantly low energy consumption.

Scaling in conventional wastewater evaporators limits the achievable evaporation rate. Thanks to the state of the art Activepowerclean technology scaling is reduced noticeably, resulting in lower amounts of evaporation residue and therefore reduced waste management cost.

Take advantage of the Activepowerclean technology: Reduced maintenance and operation efforts, increased system availability, better energy efficiency and reduced waste management cost.

More informations about VACUDEST evaporators you will find here...

H2O GmbH

Wiesenstrasse 32

79585 Steinen I Germany

Telefon: +49 7627 9239-0

E-Mail: info@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com