Contact us

Briefly explained: What does Industry 4.0 and IIoT

(Industrial Internet of Things) mean?

The world of industry is permanently facing new challenges. This includes ensuring higher product quality in the shortest possible time. The solution: digitisation and automation. This is Industry 4.0. The link between the digital and real worlds is a powerful tool for using resources efficiently and making industry more sustainable.

In concrete terms, this means that in order to get the most out of our machines while using them as gently as possible, we need to get to know them better. The term "Industrial Internet of Things" (IIoT) refers to the process of collecting huge amounts of data from intelligently networked machines in industry. Who evaluates, understands and uses it efficiently, benefits from a continuous optimization cycle and thus from high system availability and optimal machine performance with less wear.

What does IIoT mean for the VACUDEST?

By using the IIoT for the VACUDEST, our networked services not only give you an overview of your water treatment performance, but also prompt recommendations for optimization.

Optimum system availability and constantly high preparation performance of your VACUDEST

Time and operating cost savings through an optimized system

Service cost savings through preventive corrective measures

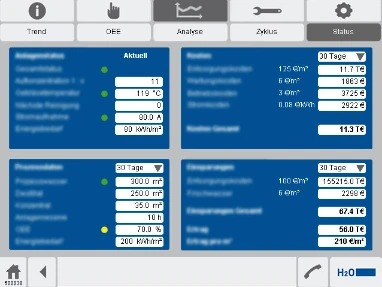

Easily accessible overview of the achievement of the expected savings of your VACUDEST

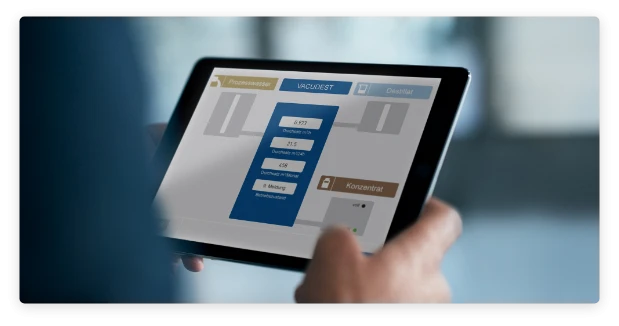

The heart of our IIoT is our convenient Vacutouch machine control. All data and analyses can be retrieved conveniently and can be used, for example, for predictive maintenance or optimization of the wastewater process.

Click through the navigation points,

to take a closer look at our smart analyses of the

under the magnifying glass.

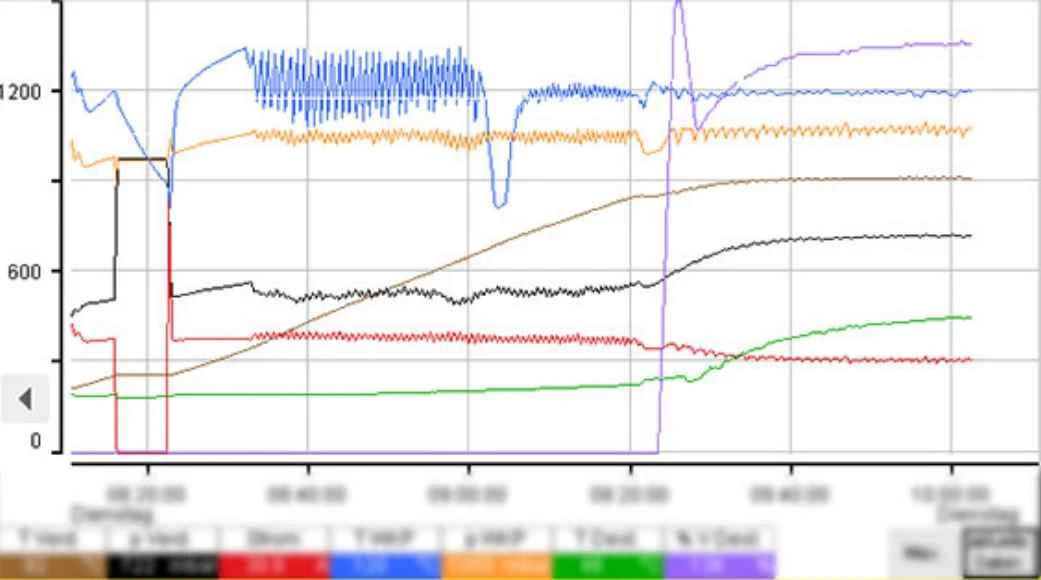

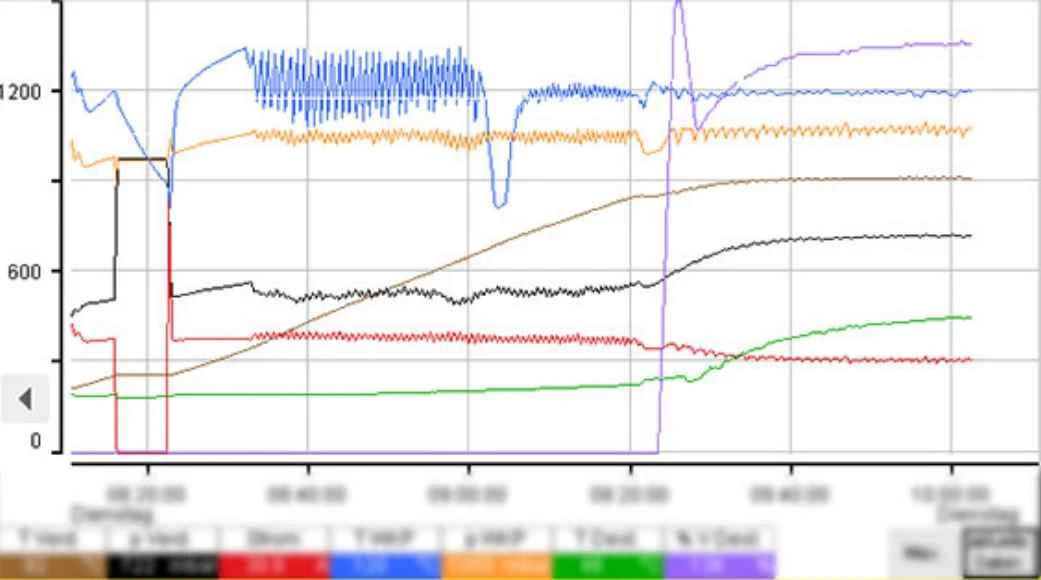

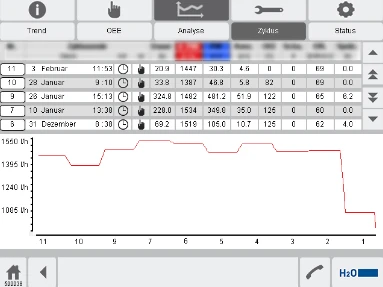

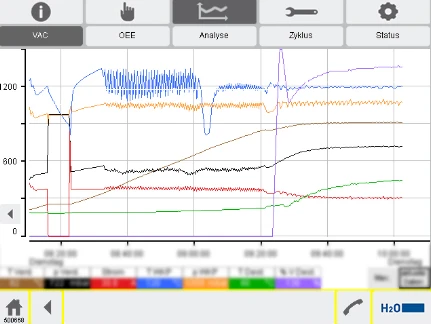

Detailed performance curves for preventive optimisation measures

Benefit: You save service costs

Quick identification of performance losses

Benefit: You increase system availability through a long-term high-performance system

Specific recommendations for action to optimise machine performance

Benefit: You save operating costs and increase system availability

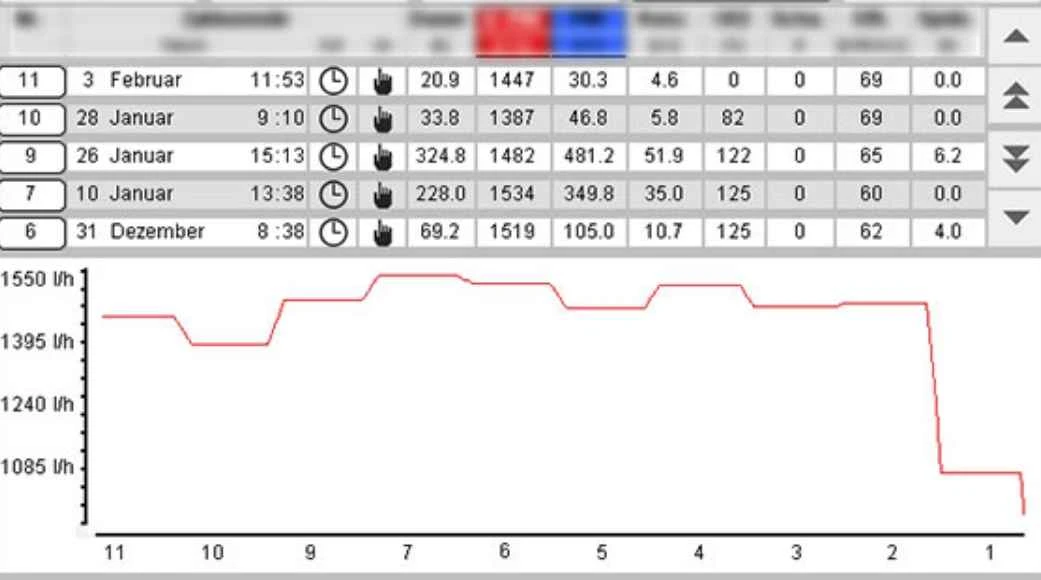

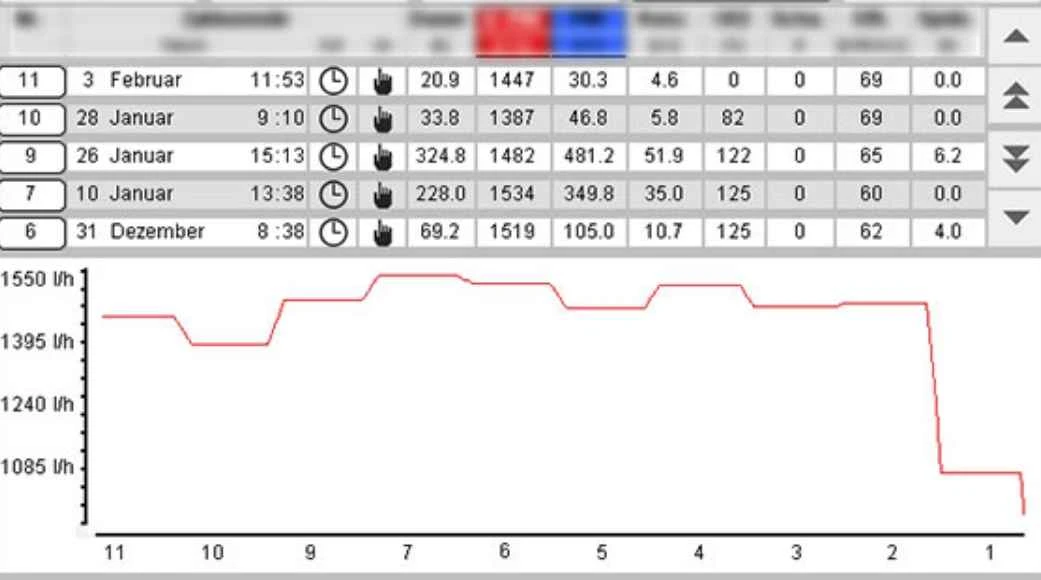

Cycle by cycle, also tracking down creeping performance losses

Benefit: You save operating costs and increase system availability

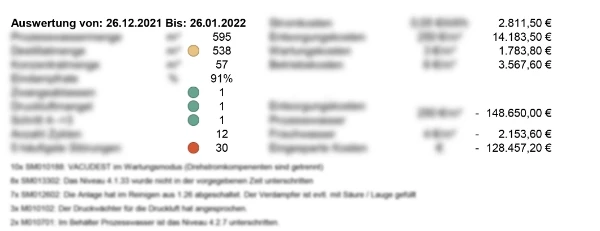

One page, one look, all the information on your wastewater treatment in an easy-to-understand traffic light system.

Benefit: Your savings in black and white - perfect for environmental audits and internal monitoring.

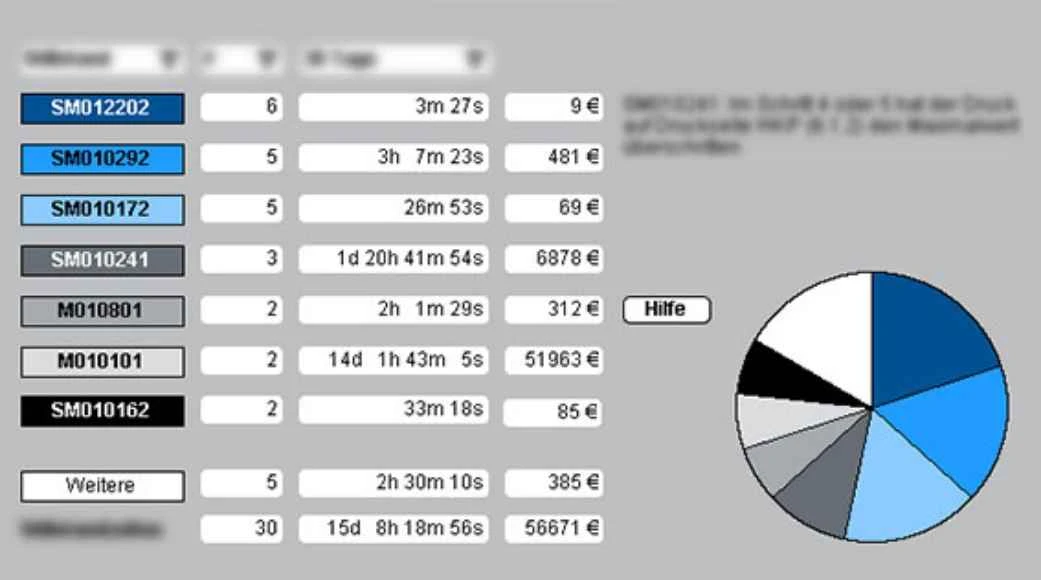

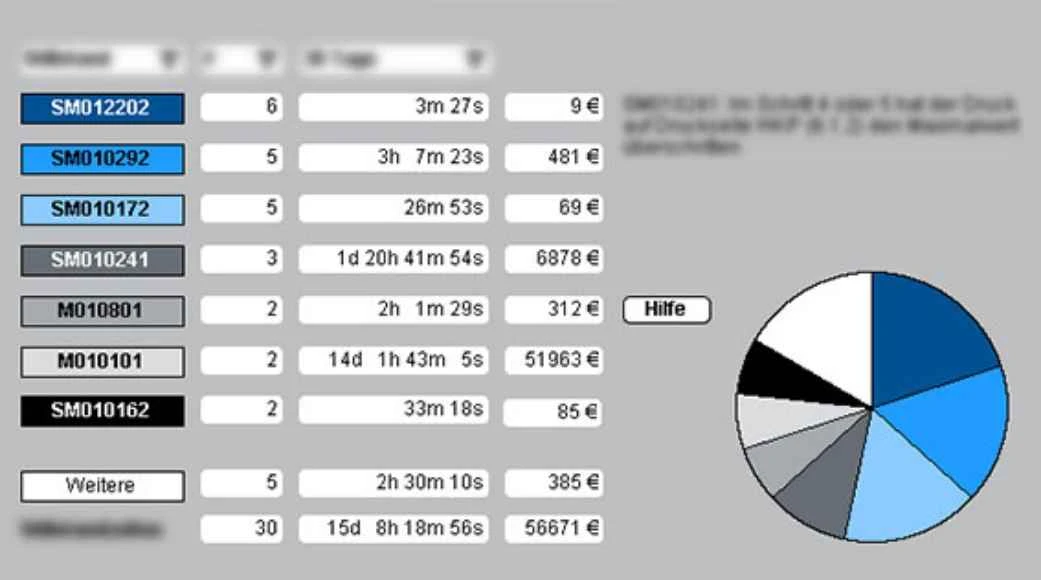

Increase the system availability of your VACUDEST through needs-based, preventive maintenance and make sure that your system runs safely, stably and without downtimes. At the same time, you can save up to 80 costs, because in the event of a loss of performance, early intervention and an on-site service visit can often be prevented.

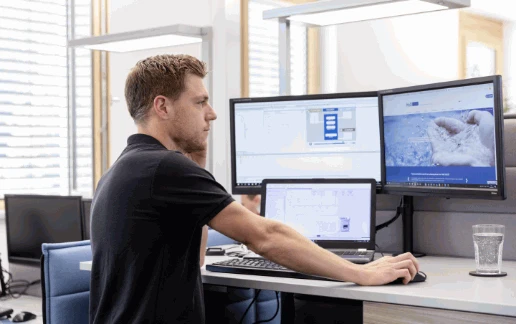

Efficient process optimization: The Vacutouch control transmits

the data from the VACUDEST directly to our technical customer consultants.

To give you an even better overview of the efficiency of your VACUDEST vacuum distillation system, we provide you with automatic, digital analyses that show you how well your system is running and where your processes have potential for optimization.

Your system is optimized perfectly via remote access. This saves time,

money and ensures optimum system availability in the long term.

Our Smart Services

at a glance

Our Smart Services Cockpits now make it even easier for you to operate your VACUDEST: See directly on the Vacutouch machine control how well your vacuum distillation system is running - and how easily you can optimise it. This way you get the best out of your wastewater treatment: more efficiency, higher process reliability, lower costs and less stress!

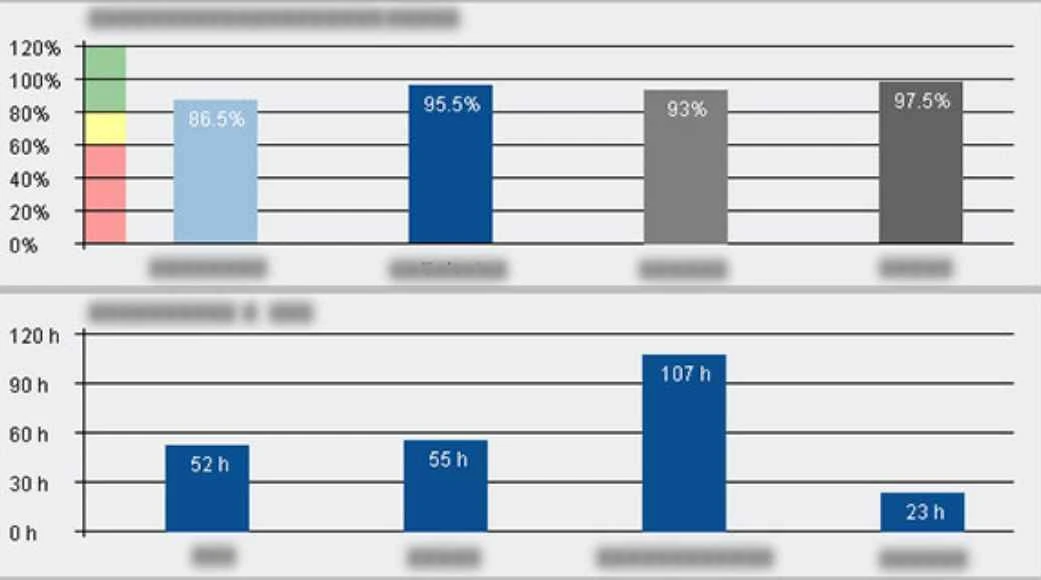

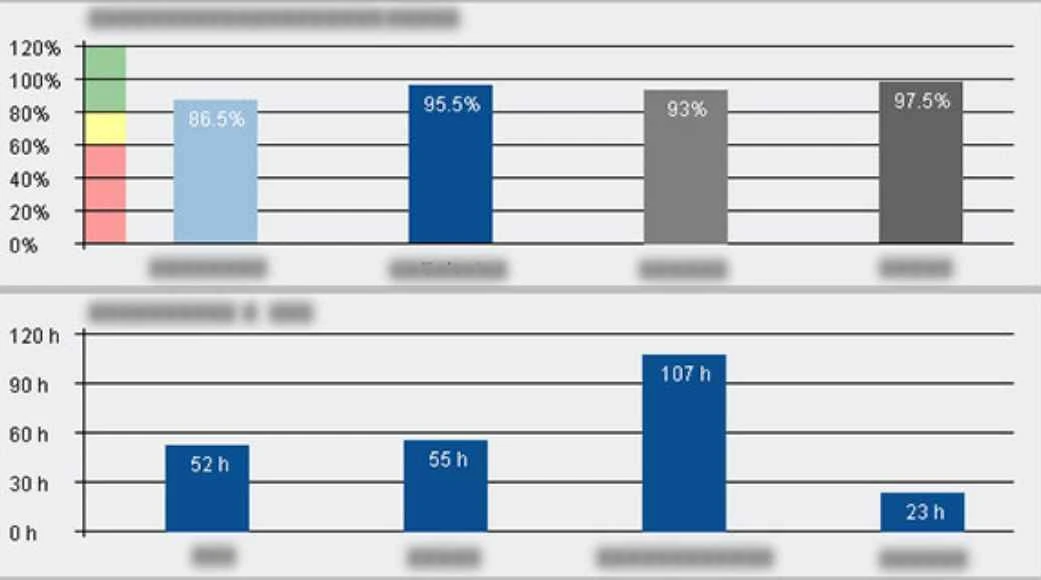

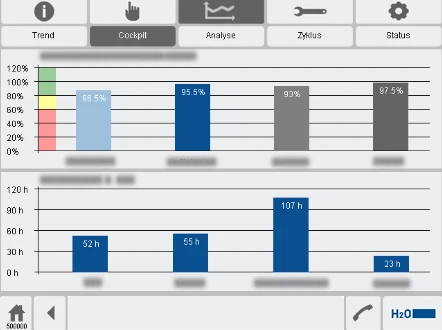

OEE Performance Cockpit (Overall Equipment Effectiveness)

The Vacutouch machine control offers you a clear 30-day statistics of the overall effectiveness of your plant.

Condition Monitoring

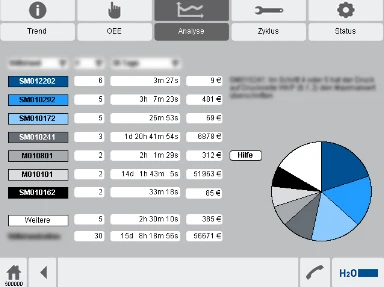

If the OEE shows potential for improvement, you can get started: Because with your new condition monitoring, optimizations are child's play! Clear statistics on your Vacutouch control system show you which optimizations will give you the highest performance gain. You can also see the savings you have made.

Analysis: Top safety news at a glance

Zyklus: Identifies long-term performance losses

Status: The entire system incl. savings at a glance

Trend Cockpit

The Trend Cockpit enables you to react before it is too late. If the plant performance decreases, this is shown in the trend diagram in real time. This enables you as the operator to intervene early with small corrective measures and counteract the costs incurred for spare parts or service calls

On just one single page, which is automatically sent to your e-mail inbox every month, you will have all the information about your VACUDEST. system at a glance. in a clear traffic light system. Perfect for your environmental audits! Our Health Report saves you time, which you can use for more important things.

We have the claim to relieve you comprehensively. That is why customer service has a high priority in our company. With our e-service, you can be sure of fast help and maximum system availability at minimum cost.

Centrally controllable:

Thanks to suitable bus interface

Well networked means being optimally informed - and guarantees high system availability of all machines integrated in the system. That is why VACUDEST vacuum distillation system can be integrated into central control systems. control systems. As interface we can offer Profibus DP, Profinet IO, OPC UA, Modbus TCP, Zenon or Ethernet IP.

Our e-Service:

Optimal system availability worldwide

If your treatment system is at a standstill or delivers inadequate results, costs are incurred. Even with optimal organization, it takes time for one of our competent service technicians to be on site. That is why we have developed flexible remote access options that save time and therefore your money. Our e-service has the potential to eliminate more than 80 percent of all unscheduled on-site service technician visits

Our e-Service remote accesses not only allow your employees to access your VACUDEST from their workplace or even worldwide, you can also authorize our VACUDEST experts to connect to your system and system and quickly analyze and resolve security messages

Should an on-site operation be necessary, it will be optimally prepared. The necessary spare parts are sent in advance and our excellently trained service technicians already have got a solution on hand. Read more about our spare parts service here.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com