Contact us

Numerous machining processes are associated with very high disposal costs for the accumulating, used cooling lubricant emulsions. This is exactly where complete systems from H2O come into play and treat such wastewater safely and in only one process step with the help of VACUDEST vacuum evaporators. By using such a system, the annual volume of wastewater to be disposed of can be drastically reduced. By using our future-oriented technology, the volume of wastewater to be disposed of can be reduced by approx. 95 %. This also reduces your disposal costs by 95 %.

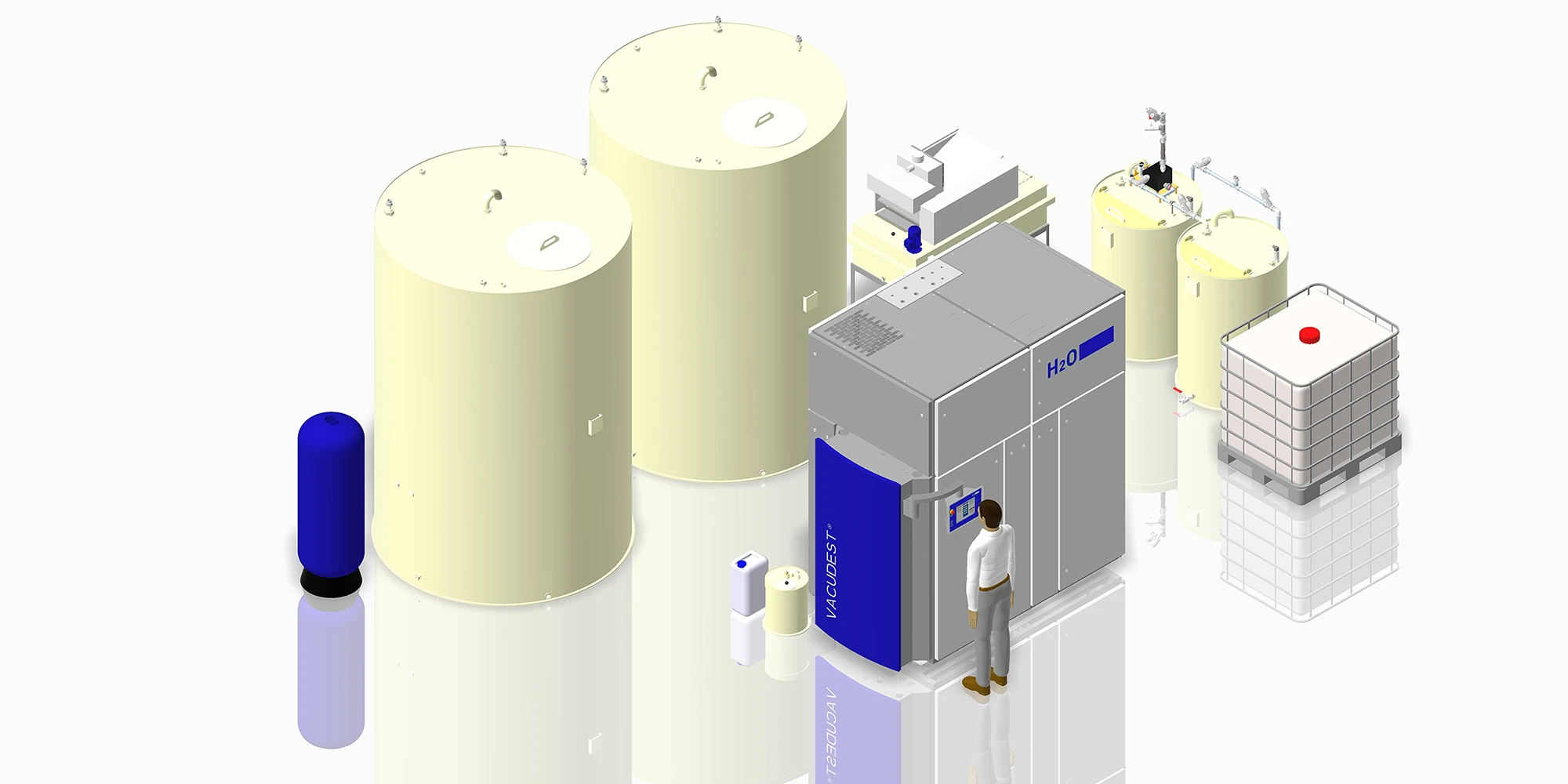

The use of VACUDEST systems is not only economical but also sustainable. The treated wastewater is so good that it can be reused in your production. Our complete systems always consider the entire process. In addition to the actual treatment of the versatile wastewater streams using vacuum evaporation, any necessary pre-treatment steps, such as the separation of chips and sludge, can also be integrated into the overall solution. In addition to these coarse impurities, used cooling lubricant emulsions from the machining processes usually contain emulsified, oily components. This is where our patented Clearcat technology gives you a decisive advantage.

Crystal clear and oil-free distillate. Oils and low-boiling components are reliably separated directly after condensation in the system. Oily residual contamination caused by co-distillation thus remains in the evaporation residue. The COD value (chemical oxygen demand) caused by mineral oils, a measure for the biological load of the water, is reduced by up to 98 %. This is an improvement of 60 % compared to single-stage distillation. In addition, the hydrocarbon index (oil index), which is caused by non-polar hydrocarbons, is lowered to < 10 mg/litre in a reliable process. A treatment with downstream technologies is often not necessary. The required limit values are safely observed and official controls no longer pose a problem.

In order to always provide our customers with the highest distillate quality, our Purecat stage was recently developed with regard to COD values. In addition to the already impressive results of the conventional Clearcat system, an even further reduction of organic components can be achieved here by means of a downstream steam wash.

A fairly simple solution usually includes a belt filter for pre-treatment, which separates coarse impurities such as metal chips. Various containers are used to collect the wastewater and to convey it from there to the VACUDEST. Your wastewater is then treated safely and efficiently.

Our innovative technologies within the VACUDEST are used to ensure that the distillate quality is always very good. Thanks to the Clearcat technology, the distillate is almost free of oil and the Destcontrol controller ensures a constantly good pH value. To prevent scaling we further use our so-called Activepowerclean whirl material.

Depending on your individual requirements, the distillate quality can be treated and further optimised by using downstream technologies such as activated carbon. In many cases, the distillate is circulated and thus reused in production. It is also possible to discharge the distillate into the sewer, as the distillate meets the quality requirements.

The solution shown here is designed for wastewater volumes of up to 2,100 m3 per year.

Do you have any questions about the wastewater treatment in your company? Contact our experts and get comprehensive advice.

For more advantages of the VACUDEST vacuum distillation units please follow the link.

Thomas Dotterweich

Senior Sales Engineer

Phone: +49 172 7004047

thomas.dotterweich@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You can find our data sheets and brochures here ...

VACUDEST distillation units are ideal for treating industrial wastewater. They can be used in a wide range of industrial applications and can be scaled to suit any capacity thanks to a variety of sizes.

Your advantages

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com