Contact us

Hardening and subsequent quenching and tempering is considered as an essential process for influencing material properties. A process which influences the material structure through rapid temperature changes. In order to achieve the necessary rapid cooling/quenching, the workpieces are exposed to different media. In addition to pure water with appropriate additives and oils, salt baths serve as a suitable quenching medium in particular. Due to an enrichment with various impurities it is necessary to exchange the baths periodically. In addition to the discarded baths in this process, large quantities of salty rinsing water from the subsequent cleaning of the parts are arising.

Due to the continuous discharge of salt solution adhering to the workpieces, significant amounts are lost over time. These losses in the molten salt usually must be compensated by new salt at high costs. Therefore, the recovery of the valuable hardening salts is often the main focus when treating rinsing water from hardening shop applications.

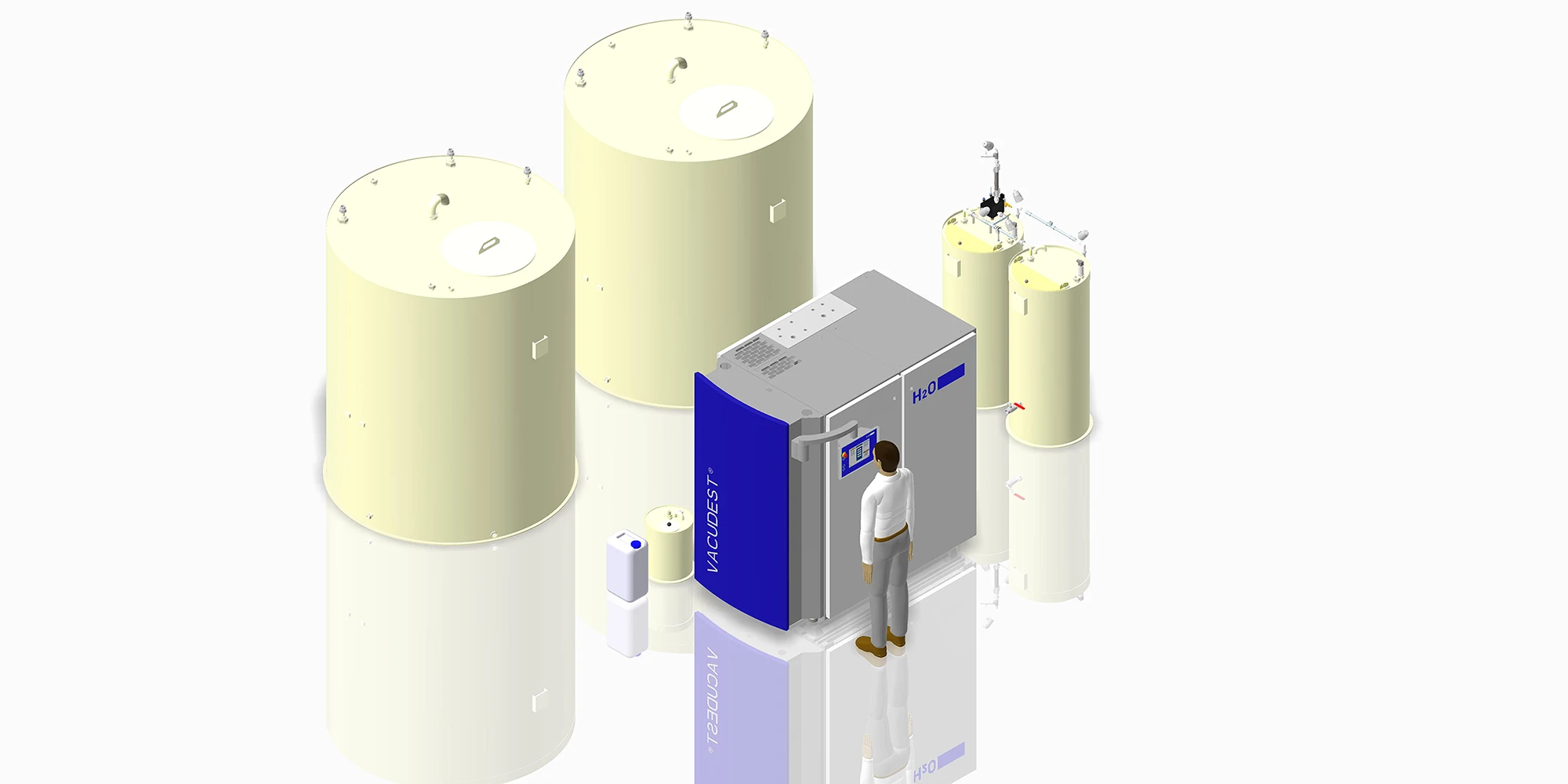

We offer you the suitable solution for this: Our VACUDEST vacuum distillation systems separate the hardening salt according to type and make it available in a sufficient concentration for the reuse in the salt bath.

The purified distillate from the evaporation can also be reused for further rinsing processes or it can be discharged into the sewer at low cost while complying with all limit values. We support you not only in the realisation of a wastewater-free production, but also offer you a complete recycling also with regard to the resource hardening salt. Profit from greatly reduced operating costs and reduce your disposal costs to a minimum.

When designing the appropriate wastewater treatment system, we rely on our many years of experience and competent application technology experts. These experts will design the optimum system based on wastewater analyses and they can also help to optimise customer processes.

Find out more about the work of our application centre for wastewater-free production.

As in the example shown, a complete solution for up to 600 m³ per year, the rinsing water reaches the VACUDEST with the help of an automatically controlled pump. The wastewater is evaporated and optimally treated for your purposes.

Our integrated Activepowerclean technology constantly cleans the system, preventing the formation of deposits and ensuring optimum system availability.

The entire fully automatic process is visualised, regulated and monitored by our Vacutouch control system specially developed for this purpose. An additionally installed air conditioning unit as well as fans and air coolers guarantee optimal temperature conditions, completely independent of external influences.

Are you already thinking about sustainable wastewater treatment in your production? Our experts will be happy to support you to find the right system for you.

For more advantages of the VACUDEST vacuum distillation units please follow the link.

Thomas Dotterweich

Senior Sales Engineer

Phone: +49 172 7004047

thomas.dotterweich@h2o-de.com

News from the leaders in zero liquid discharge production you will find here...

Of 100% industrial wastewater, we make 95% pure distillate. How? That explains our 3D animated film!

You can find our data sheets and brochures here ...

VACUDEST distillation units are ideal for treating industrial wastewater. They can be used in a wide range of industrial applications and can be scaled to suit any capacity thanks to a variety of sizes.

Your advantages

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com