Contact us

In this article you will find detailed information on how to install a VACUDEST vacuum distillation system. In addition to the prerequisites and the integral components of the technology, the installation and the commissioning procedures are also featured.

In this article you will find detailed information on how to install a VACUDEST vacuum distillation unit in your plant. It is often difficult to decide on the implementation of a new method of handling production wastewater. Existing technology is known and anything novel requires training, which is an extra effort on resources. Questions arise, for example, on how the ongoing operation can be maintained during the transition and there is also concern about problems that could surface any time. The experts at H2O GmbH have therefore developed techniques that make it as smooth as possible to integrate vacuum distillation into the ongoing operation.

In order to successfully integrate a VACUDEST vacuum distillation unit into the operation, the following site properties are required:

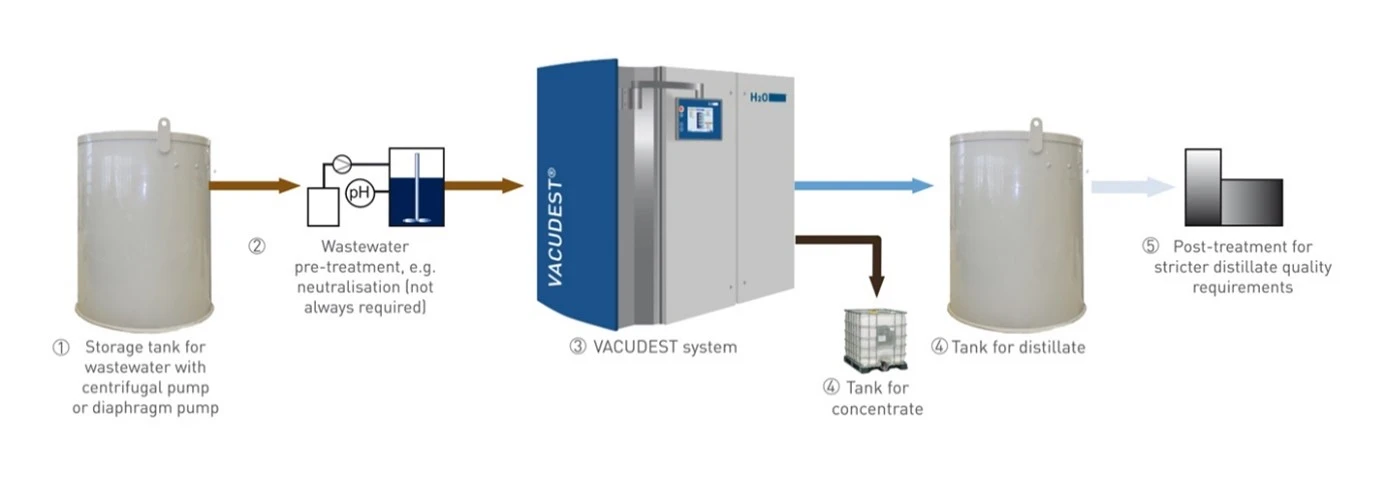

A typical vacuum distillation plant consists of the following components, which can be integrated into the production pipeline:

This tank is usually made of plastic and can hold 1.5 to 2 daily volumes of process water. Depending on the type of wastewater and the installation regularities on site, this tank can be single-walled or double-walled. Double-walled collection tanks or a collection tray around the entire system must be used due to official regulations in water protection areas. This prevents any possible leakage of process water into the ground. The catch basin must be able to hold the entire volume of process water that can be contained in the tank. In addition, it must have an overfill protection or a leakage monitoring system. Whether a tank is single-walled or double-walled also influences the type of pump used to pump the process water from the process water tank into the vacuum distillation unit.

If, due to the impurities contained in the process water produced and the regionally applicable water protection ordinances, a single-walled tank is permitted, an electrically operated centrifugal pump can be utilized. A centrifugal pump is as such not self-priming and therefore will have to penetrate the shell of the tank during installation. For hydrostatic reasons, it can only be used in the lower area of the tank.

In the case of existing ground tanks, an air-operated diaphragm pump is mandatory. If even more safety is required due to water protection regulations, a diaphragm pump is used so that the protective function of the double walls is not compromised.

More detailed information on the pumps used in the vacuum distillation process.

If the process water cannot be fed directly into the vacuum evaporator due to various reasons, wastewater pre-treatment has to be carried out further upstream:

Since a neutral to slightly alkaline pH value (7 to 9.5) of the wastewater is required for treatment with a vacuum evaporation plant, pre-treatment must be carried out; otherwise, a too low pH value can lead to corrosion of the system.

For this purpose, the process water is pumped into a neutralisation tank equipped with various measuring devices (pH and temperature, level detection, as well as dosing pumps for acid, alkali or both). The pH value is adjusted gradually to a value of 7 to 9.5 by adding acid or lye in order to prepare the process water for the evaporation process. Only water with the correct pH value is permitted to enter the VACUDEST.

In the case of slightly acidic or slightly alkaline wastewater, this stage can be dispensed with completely, as a pH controller integrated in the vacuum distillation unit then ensures a constant pH value even without conventional continuous neutralisation.

The Destcontrol ph control module from H2O GmbH reliably achieves stable pH values and thus replaces conventional continuous neutralisation, e.g. in paint pretreatment or aluminum die casting.

The process water to be fed to industrial vacuum distillation often contains contamination in the form of sludge or oils. In these cases, various filter systems, such as belt filters or three-phase separators, are used upstream of the vacuum distillation unit:

It is important to remove solids and oils before they enter the vacuum distillation unit, otherwise the performance and efficiency of the vacuum distillation will be significantly reduced.

Tip: A belt filter is often installed straight after the wastewater collection tank and the three-phase separator in bypass mode. This means it is connected to the process water tank and continuously pre-filters the process water.

To ensure that the vacuum distillation system works more efficiently and generates maximum savings, the three-phase separator filters out solids and oils that were previously easy to separate.

Especially in the case of organically polluted wastewater, biological processes can cause a rotten smell in the process water tank. The tank should be aerated for prevention. The H2O team uses the Jetflex in such cases. It is suitable, for example, for aerating cooling lubricants, washing water and degreasing baths. In this process, small air bubbles are forced into the wastewater by means of compressed air, which are distributed in the wastewater and rise to the surface. This enriches the wastewater with oxygen and prevents the smell of rotting matter.

The center of a wastewater treatment system is often a vacuum distillation unit, also known as a vacuum distillation core system. This core can treat the wastewater from production in an energy-efficient way thanks to evaporation under vacuum – since under vacuum, water evaporates at around 80 instead of 100 degrees Celsius. During this step, the volume of wastewater is reduced enormously, as 100 % contaminated wastewater becomes up to 98 % clean distillate and only 2 % concentrate remains.

The system is supplied, installed and commissioned by H2O. In addition, H2O also supplies all the operating materials associated with and necessary for the system, such as defoamers and cleaning agents optimally matched to the process water.

The customer care service concept of H2O GmbH includes personal, telephone and remote service support. And helps with the selection of suitable equipment.

If the system identifies increased foaming inside, a defoamer liquid is introduced into the system from the defoamer tank, which breaks up the foam thereby reducing it. Foam can occur if the wastewater contains oils, fats, proteins, emulsifiers or surfactants.

Depending on the size of the plant, the tanks are specified for the distillate or for the residues to be disposed of. The tanks can be supplied by H2O or the customer can provide suitable tanks which are then retrofitted with the necessary level control equipment. This makes sense, for example, if the system is to be implemented abroad avoiding high shipping and transport costs for virtually empty containers.

The tanks for concentrate and distillate are defined to match the size of the plant. Shown here are tanks for a wastewater volume of up to 8,000 cubic metres per year.

The residue discharged from the system is still liquid and flowable. The VACUDEST automatically empties its concentrate into the concentrate tank. It can be manufactured with all the connections required by the customer. If required, a tanker connection can be provided through which the disposal company's tanker can pump the concentrate directly.

The size of the tank is selected to suit the future use of the distillate. At the moment, about 30 % of H2O's customers operating industrial vacuum distillation plants discharge the distillate into the public sewer system. About 70 % of customers reuse the distillate obtained in their own industrial operations. This closed-loop use saves large quantities of fresh water.

In most cases, the distillate can continue to be used in operation after VACUDEST vacuum distillation or can be fed directly into the sewer.

Ion exchanger: An ion exchanger removes residual salts from the purified water.

If a customer has stricter requirements for conductivity than can be obtained directly via the vacuum distillation plant, an ion exchanger can be installed downstream to remove salts. This is often necessary in electroplating, because ultra-pure water is needed here, which must not be contaminated by salts. Any residual salts will cause deposits on the workpiece preventing a durable paint finish.

If stricter limit values for organic contamination (COD) have to be observed, the innovative Purecat technology from H2O GmbH is frequently used. The PURECAT reduces the already low COD value after vacuum distillation by another 50 percent.

In the case of very high COD content in the distillate concomitant with very strict limit values, further post-treatment is necessary. Activated carbon filters are used for non-polar organic substances such as fats and oils. The Oxydest technology of H2O GmbH effectively reduces polar organic substances such as alcohols, solvents or API by means of UV/peroxide.

Even more operating and disposal costs can be reduced with a ZLD post-concentrator : it reduces the still flowable residue from the vacuum distillation plant by another 50 per cent and thus also reduces the disposal costs by half.

The ZLD post-concentrator saves disposal costs by minimising the residue: In the small bottle on the left, the still liquid concentrate from the VACUDEST, on the right further concentrated with the ZLD.

The installation of a VACUDEST vacuum distillation unit usually takes 2-3 weeks. During this time, the customer retains the previous handling of his process water. If the process water was previously disposed of, the water will continue to be disposed of during the transition period. If chemical physical cleaning was used before, this process can also be continued during the transition period. Should the VACUDEST be installed at the location where previous technology was installed and is now being replaced, a temporary storage facility can also be created to bridge the gap until the vacuum distillation plant is installed and ready for operation.

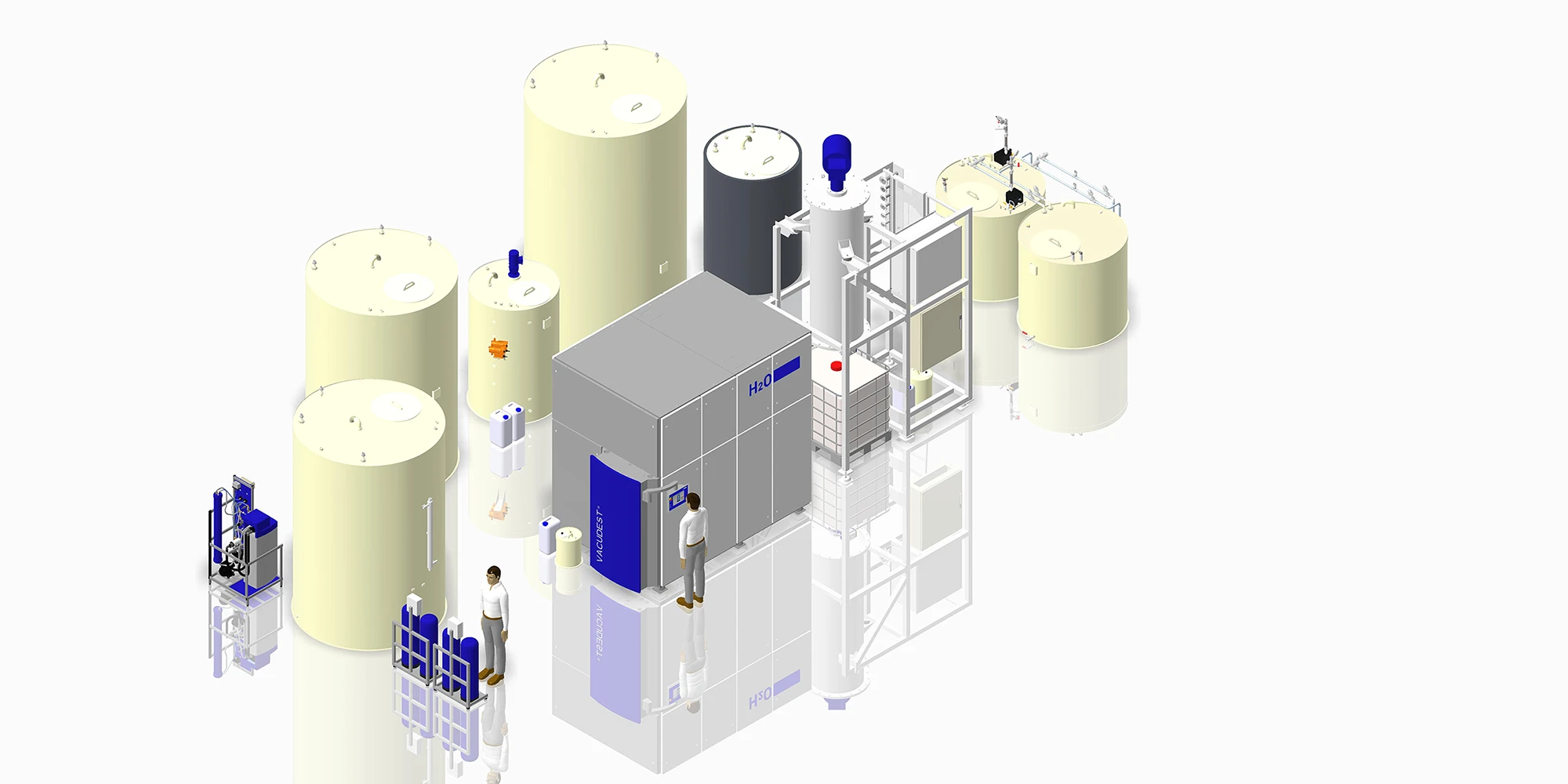

An ortographic digital representation of a vacuum distillation plant.

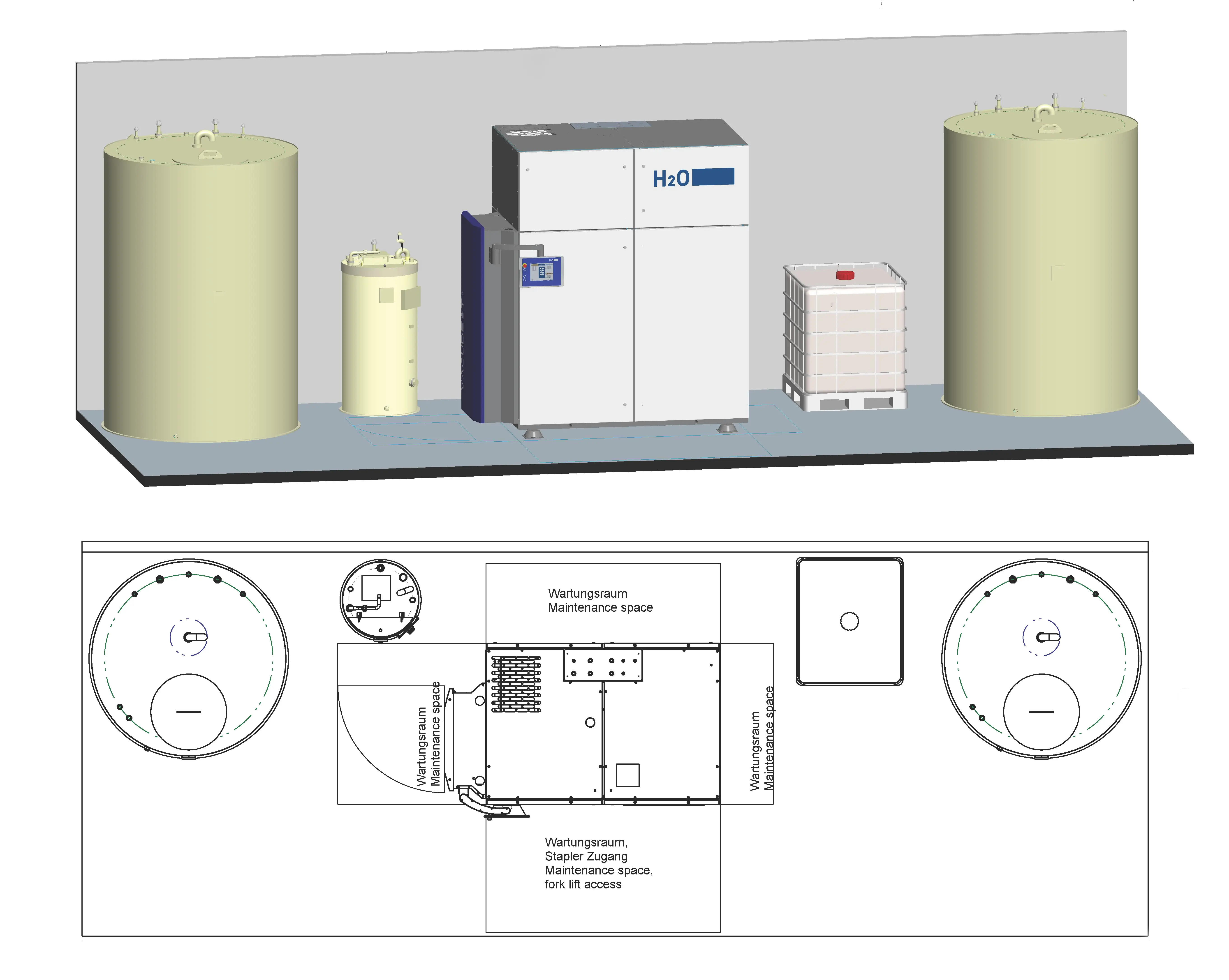

As a rule, H2O must receive a floor plan from the customer. All the components of the VACUDEST system are then positioned on this plan. If the installation site is in Germany or in the surrounding countries, an H2O employee can also carry out an on-site inspection and measurement. It is important that the maintenance and safety areas are free and respected. The individual components do not have to be located in the same room but can be distributed in different rooms or even on different floors. Precise planning of the installation is important to ensure the function of all components and also to be able to install the piping and installation of the system well right from the start.

The space requirement is determined individually based on the size of the system and the required additional components.

The installation plan - here of the VACUDEST M - includes the layout of the entire wastewater treatment system and the space requirements for maintenance work.

The installation plan - here of the VACUDEST M - includes the layout of the entire wastewater treatment system and the space requirements for maintenance work.

Before the system is delivered and H2O's installation experts are on site, all necessary breakthroughs for pipelines should be made and the site where the system is to be installed should be cleared. After delivery of the components, the customer transports them to the desired installation site and positions them according to the installation plan. H2O then sends the experts to install the system.

The H2O installation team, consisting of two employees, is usually on site for one to three weeks. During this time, the pipelines are laid in stainless steel. All electrical components are wired and connected to the system. In addition, the compressed air is connected to the pneumatically operated components. The entire installation of the new wastewater treatment system takes between 1 and 3 weeks, depending on the project.

The H2O service technicians put the system through its paces and tailor the system to the process water at the site. Commissioning is closely monitored. At the same time, the customer's personnel are trained hands-on directly on the system. Depending on the complexity of the system, this process can take between less than a week and or around two weeks.

Afterwards, the system is handed over to the customer. Of course, the H2O team is also available any time for questions after the installation. The H2O service department can be reached directly and quickly via the specially set-up service hotline. In order to ensure high system availability, less downtime and a long-lasting high efficiency of your new wastewater treatment system, H2O GmbH has also developed the Customer Care Concept. It supports customers with regular on-site maintenance, maintenance via phone, remotely and also through the help of digital analysis tools such as the so-called Smart Services.

The H2O GmbH team accompanies its customers through the entire life cycle of the system, from the selection and planning of the right system, through installation and commissioning to maintenance in order to preserve the value of your new wastewater system. Our solutions sound reasonable and appeal to you?

Contact our experts, we will find the right, tailor-made solution for your production together with you. It will be not only beneficial for the environment, but also for your wallet.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com