Contact us

"The Harting Technology Group is a leading international supplier of industrial connection technology for the three lifelines data, signal and power with 13 production facilities and 44 sales companies worldwide" (www.harting.com/unternehmen). As a family-owned company with a long tradition spanning more than seven decades, ecological responsibility is a fundamental component of the Harting Technology Group's actions. Thus, the course towards wastewater-free production with the VACUDEST process was set early on at the main plant in Espelkamp. This fundamental decision in favour of ecologically sensible action in combination with economic considerations was also already supported during the company's development in China.

Internationally leading supplier of industrial connection technology for the three lifelines Data, Signal and Power.

At the Harting plant in Switzerland, Harting AG in Biel, production had to be expanded and an investment in the existing wastewater plant was necessary. Up to now, the legally compliant wastewater treatment has been carried out using the classic method of chemical-physical treatment with precipitation, flocculation and filtration via a chamber filter press. Subsequently, the heavy metal-free but saline wastewater was discharged into the local sewerage system. The sludge, which was produced during the pressing process and still contains a lot of water, was disposed of externally.

With regard to the new investment and the leading environmental idea, the Harting company was faced with an important question. Should the legally compliant, but meanwhile outdated technology be modernized and adapted to the expanded production - or should a completely new, modern and sustainable concept be preferred? After thoroughly weighing up all the arguments: suitability, reliability, ease of operation, cost-effectiveness and, last but not least, environmental benefits, the decision was made in favour of the vacuum evaporation system from H2O. This decision was also made easier by the experience with H2O and the VACUDEST system in the Harting plants in Espelkamp (D) and Guangdong (CN).

After detailed consultation and analysis of the process water streams, the process analysis was carried out in the laboratory of H2O GmbH in Steinen using a representative water sample. Here it already became apparent that the evaporation residues could possibly be used in a metallurgical plant. This was also confirmed in practice. In addition, the nickel emissions in the waste water could be reduced to zero, which was almost impossible with the old, conventional precipitation/flocculation process.

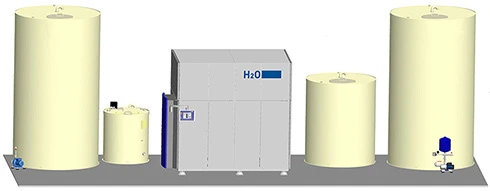

To implement the wastewater concept, Harting AG ordered a VACUDEST L 3.000, which was delivered in the highly corrosion-resistant version (material level 2) due to the expected salt concentrations. H2O GmbH was able to integrate several components and containers from the existing, and in the meantime partially deconstructed, waste water plant into the new waste water concept, so that a further savings potential could be realized. Due to the competent and good cooperation with the employees at the location Biel, it was possible to install the VACUDEST cleanly and to put it into operation very quickly, despite the partly tight space conditions.

To implement the wastewater concept, Harting AG ordered a VACUDEST L 3.000, which was delivered in the highly corrosion-resistant version (material level 2) due to the expected salt concentrations. H2O GmbH was able to integrate several components and containers from the existing, and in the meantime partially deconstructed, waste water plant into the new waste water concept, so that a further savings potential could be realized.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com