Contact us

20 years of H2O – two decades worth of experience. Many years of experience, including from the customers who use our systems. How did things used to be? What has happened since? To find that out, we visited one of our oldest clients. Believe it or not, they have been running a VACUDEST system to treat their stainless steel pickling water for 28 years. Before H2O was founded, Matthias Fickenscher, the current CEO, worked in sales at Mannesmann Demag Wittig. With the management buy-out 20 years ago, H2O GmbH also acquired the rights to the VACUDEST vacuum distillation systems. The bottom line following our visit: the old lady may be getting on in years, but she’s still doing what she was intended to do. Impressive!

This global company produces stainless steel containers in various sizes. In order to manufacture these stainless steel containers in accordance with their clients’ strict safety and hygiene standards, the company takes care to ensure the highest quality when processing the stainless steel raw material. The result of the various processing steps is a completely homogeneous surface.

Once processing is complete, the containers are washed. This wastewater is treated by the VACUDEST vacuum distillation system. The quality of the treated water is so good that it can be discharged into the sewage system. “We have never had any problems from the authorities. After all these years, the old lady is still performing as well as ever!” confirms the company’s VACUDEST supervisor.

Example of a processed surface.

And why did the company procure the VACUDEST in the first place 28 years ago? “Before we acquired the VACUDEST, we disposed of absolutely all the washing water. So, by procuring this water treatment system, we were able to make huge savings on disposal costs,” he recalls. In addition, the basic idea of protecting the environment seemed like a “great thing”.

Nonetheless, the old lady is now showing a few signs of her age. “She overheats occasionally and the mechanical sensors jam more frequently due to microparticles in the washing water.” This is a good example of how the systems have been enhanced over the years: nowadays we use electrical sensors – so “jamming” is no longer possible. “But we can quickly resolve any little problems like this ourselves. Over the decades the machine has been with us, we’ve got to know it inside out and we know exactly where any problem is.”

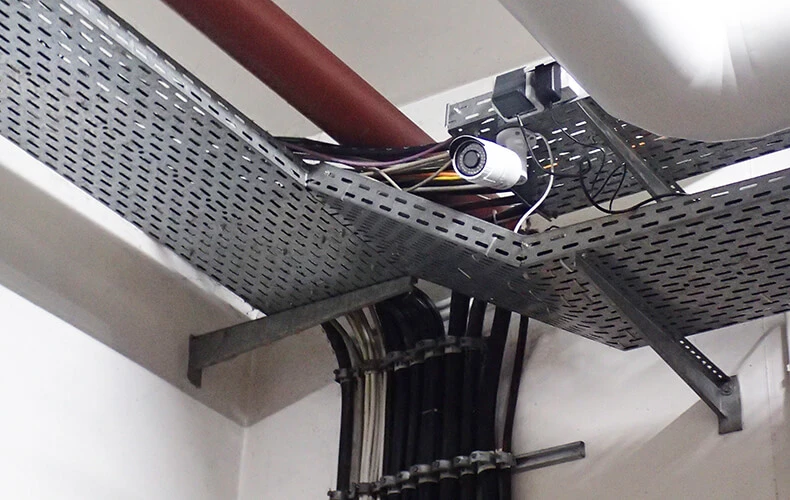

A self-installed camera monitors the status of the VACUDEST. “So I can react immediately,” explains the VACUDEST operator. In newer machines, this function is already integrated: here, the user is notified automatically via their mobile phone.

To help monitor the machine, there is a self-installed camera opposite the system. “That means I can see straight away if something isn’t right and I can react immediately.” Here again there have been plenty of changes with the newer, more modern VACUDEST systems. Today the machines automatically issue an alert to the user’s mobile phone in the event of a fault. However, the camera is a great idea and works in the same way.

Despite a few age-related shortcomings and the additional effort required to deal with them, the company is still satisfied with the VACUDEST. And what about their experiences with H2O? “Our interactions with the staff at H2O are excellent. Any spare parts required due to wear and tear are always delivered in a flash.”

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com