Contact us

Design Inox Vendée's requirements for a modern wastewater treatment system were, above all, a fully automated system and a reduction in process costs.

The solution: a fully automated VACUDEST vacuum distillation system and the reduction of waste to an absolute minimum.

Design Inox Vendée manufactures stainless steel and aluminium parts for numerous industries, integrating the following surface treatments: Pickling and passivation of stainless steel, electropolishing.

The machine is reliable and requires little monitoring and maintenance, which has allowed us to achieve our goals and reuse our process water.

The production of stainless steel parts generates two types of waste water from surface treatment:

The acidic process water produced during these processes, up to 1 m3/day, was previously stored in two tanks and taken over by a waste disposal company.

Design Inox Vendée wanted to reposition themselves and had the following requirements for wastewater treatment on site:

As a first step, the H2O GmbH wastewater-free production application centre drew up a complete balance sheet of the wastewater flows and the corresponding volumes. Critical substances from electropolishing or the passivation of stainless steel were also analysed. This part is crucial in order to avoid possible damage to the evaporator.

In the case of DIV, all products used in the process are suitable for treatment using vacuum distillation. The low content of chlorides, fluorides and other corrosive compounds in the waste water allows the use of standard stainless steel for all parts in contact with wastewater. For higher concentrations, more corrosion-resistant steel grades can be chosen.

The upstream storage capacities are used to store the contaminated wastewater. A neutralisation tank is provided to adjust the pH value, as the evaporator cannot process acidic waste water. A distillate tank with lifting station and a 1 m³ IBC container for the concentrate are also utilized.

Once the basis for the new wastewater solution had been created, the customer's specific requirements were analysed in more detail again:

The latest generation of the VACUDEST vacuum evaporator is equipped with the modern Vacutouch control system, which also offers the option of remote maintenance by our customer service team.

The distillation test carried out in H2O's own application centre resulted in 6% concentrate, which ultimately has to be disposed of. By reducing the volume of waste to 6%, the customer can reuse the remaining 94% as a completely clean distillate with very low conductivity (below that of tap water). This results in streak-free surfaces on the parts after rinsing. The selected Clearcat module, an oil separator integrated into the evaporator without consumables, eliminates the need for conventional post-treatment. This makes the system more compact and simpler.

The VACUDEST XS 300 Clearcat vacuum evaporator, which can process up to 1 m³/day with a concentration factor of at least 16 or a maximum of 6 % concentrate, fulfils the customer requirements. Design Inox Vendée opted for this solution and was thus able to limit the number of waste disposal vehicles travelling to and from the site.

Where other processes with a lot of equipment and operating costs barely meet the legal discharge limits, the Clearcat condensation stage impresses with the quality of the treated wastewater.

It is crystal clear and practically oil-free.

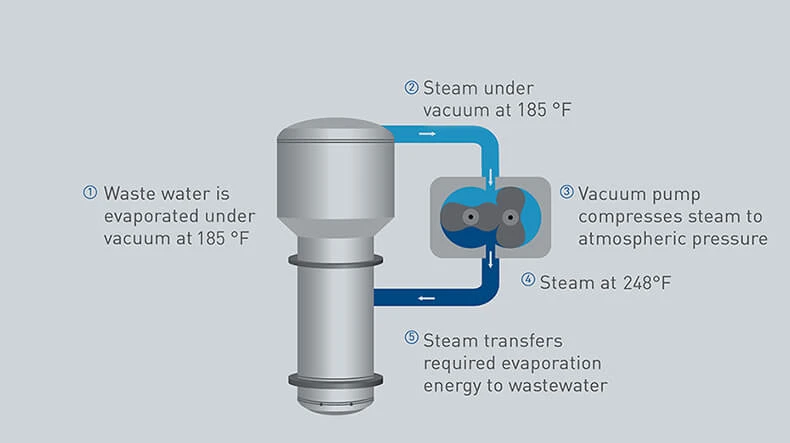

Vacuum evaporators are based on the simple principle of separating substances based on their different boiling points. During evaporation, compounds whose boiling point is higher than that of water remain in the concentrate. These include heavy metals, salts, oils, fats or surfactants.

The rising water vapour is virtually free of impurities. After condensation, it can be fed back into production. In this way, you produce completely wastewater-free.

You can find the video on our VACUDEST functional principle here

Our modern Vacutouch machine control system enables convenient remote access to your VACUDEST vacuum evaporator via the Internet. This applies not only to us, but also to your operators.

This saves time and money, as 4 out of 10 faults can be rectified without on-site intervention.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com