Contact us

Our customer, who assembles and coats high-frequency connectors, wanted a sustainable wastewater treatment system that requires minimal operating effort and whose treatment quality is sufficient to enable recycling of the electroplating wastewater. Based on positive experiences at another branch in the group of companies, the customer once again opted for a sustainable VACUDEST vacuum distillation system with innovative modules that would met the quality and sustainability requirements. Already in the first year after implementation, the company saved over 1 million litres of fresh water by using this modern technology.

Our customer assembles and coats high-frequency connectors and cable assemblies for mobile and telecommunications, industrial measurement technology, automotive, medical and industrial electronics, data technology and aerospace technology.

"In times when fresh water reserves are becoming increasingly scarce, everyone should think about this type of treatment."

Previously, the rinsing water from the galvanic surface finishing process was processed using conventional chemical-physical treatment with precipitation, flocculation and filter presses and the resulting waste water was discharged into the sewerage system after a further, energy-intensive UV treatment. This method was very labour- and cost-intensive and is dependent on discharge controls and permits. After the permitted discharge volume could no longer keep up with the wastewater volumes produced, other treatment methods were sought.

The aim was to reduce the amount of work and waste, minimising costs and staff requirements and reuse the water in the most environmentally friendly way possible. As a VACUDEST vacuum distillation system with recirculation has already been used successfully at the subsidiary plant in China, the experts at H2O GmbH were also approached for the next project.

The project began with an analysis of the customer-specific process water in the laboratory of H2O GmbH's application centre for wastewater-free production. The result: "Yes" to the implementation of a wastewater-free electroplating. This is because the desired high distillate quality and waste quantities of less than 4 per cent were achieved with vacuum distillation technology.

Safe, economical and high quality: the compact VACUDEST M 1.500 vacuum distillation system fulfils all requirements.

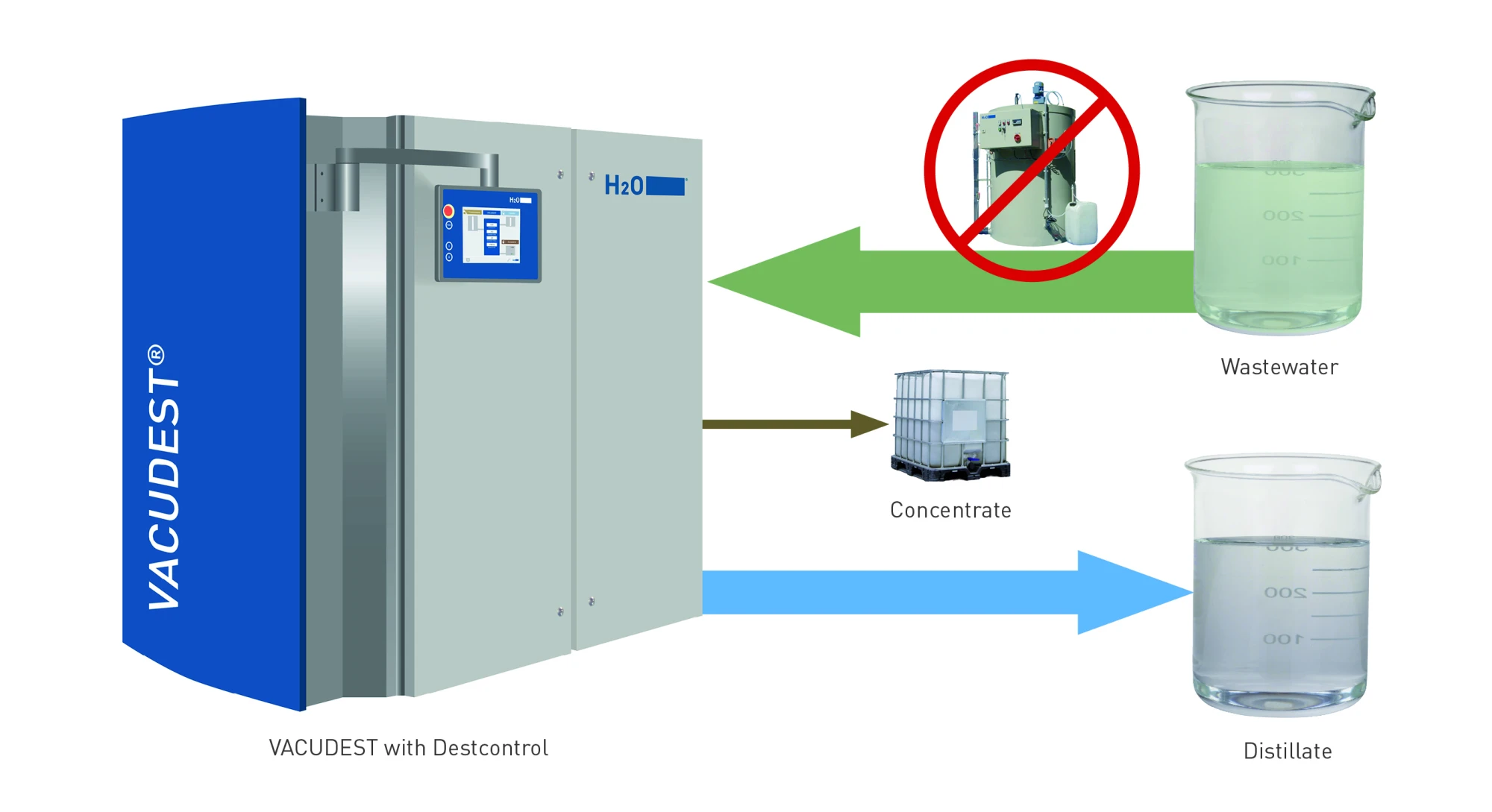

Destcontrol technology was also used to provide additional protection against fluctuating pH values in the distillate. This module integrated into the VACUDEST can be applied wherever constant distillate quality is required for circulation. The Destcontrol is particularly suitable for alkaline or slightly acidic water. It replaces conventional, continuous neutralisation. The pH value is not measured in the feed as in conventional evaporator systems, but in the purified distillate. If the pH values change here, neutralising agent is dosed directly into the VACUDEST evaporator sump for correction. Any potential post-reactionsthat occur, which could cause damage to the system, are compensated for. A consistently stable distillate quality is achieved. Ideal for safe discharge or recycling.

Destcontrol technology replaces continuous neutralisation and ensures a stable pH value in the treated water.

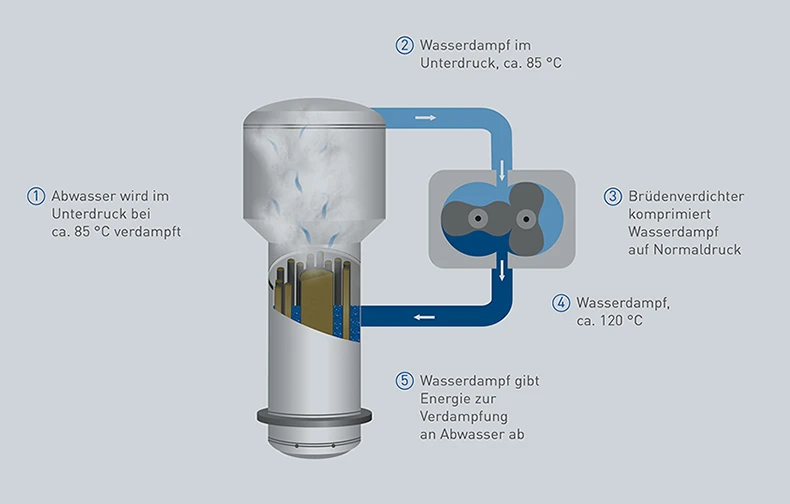

Vacuum distillation plants work on the simple principle of separating substances according to boiling point differences: The industrial wastewater is evaporated under a reduced pressure at a temperature of only about 80 degrees, instead of 100 degrees as at atmospheric pressure. All substances that have a higher boiling point than water remain in the evaporation residue. This includes heavy metals, salts, but also oils, fats or surfactants. Because the water content is evaporated, the volume of the residue from distillation is reduced to 0.5 to 5 per cent of the original wastewater volume. The rising steam, also called vapor, is almost free of impurities. After condensation, it can be returned to the production as clean process water.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com