Contact us

Innovative vacuum distillation technology from H2O reliably ensures compliance with strict limits for disposal of water into watercourses.

On landfills leachate occurs from condensation, which normally is heavily contaminated with pollutants. Percolation into the ground-water is, because of the nitrogen compound and organic contamination, not allowed. To reach the strict values for disposal such leachate needs to be collected and trated. In November 2009, an ultramodern leachate treatment system was installed in Mallabia (Basque country) by the disposal-consortium BETEARTE, which consists of the 3 biggest waste-companies in Spain. The picture below shows the plant, which has been built by SIDASA. The objective was to use most modern technology, working economically and complying reliably with the strict legal limits for disposal.

The leachate occuring at the 2 million ton landfill is collected in a 5.000 m³ tank before it is pumped to a chemical/physical pretreatment. By precipitation and floculation the contaminat concentration in the leachate is reduced; however the strict legal limits for disposal can not be reached. This is achieved by treating the leachate with vacuum distillation. In the core part of the plant the process water is evaporated under vacuum at 700 mbar by 2 VACUDEST L 6.000. Heavy metals, organic components, as well as salts are separated reliably from the clean water. The steam that occurs, is compressed inside a roots pump to ambient pressure. During compression the steam temperature raises to 120° C. This superheated, sterilized steam is reused as heating medium for the leachate entering the VACUDEST vacuum distillation system. In this way, the system uses – compared to atmospheric distillation – 95 % less energy.

The 2 VACUDEST L 6.000 (treating 12.000 m³/a), which are installed at BETEARTE were especially optimised to recycle landfill leachate. Because of the high chloride concentration in the distillate, a special material had to be used, to avoid corrosion. The integrated, hydrodynamic, optimised Activepowerclean system ensures a clean heat exchanger and allows high evaporation rates. Compared to conventional vacuum distillation systems, the energy consumption is reduced by 15 % and high evaporation rates allow reduced disposal costs for the concentrate.

During start-up, the process water could be concentrated 20 times, which was far better than expected initially. The quality of the treated water is so high, that it can be disposed into a river.

When treating landfill leachate, there are many different methods. Typical treatments contain reverse osmosis, or ion exchangers.

To make sure, the strict disposal limits can be reached, VACUDEST vacuum distillation systems are recommended since they are capable of separating numerous harmful substances. With a VACUDEST vacuum distillation system it is possible to concentrate these substances with lowest energy consumption. Because of that, several waste management companies e.g. Befesa from Spain or Veolia from France already decided to treat their process water with the H2O VACUDEST vacuum destillation systems.

“We can recommend H2O with full conviction. Because thanks to them, we can fully concentrate on our production."

Where other processes barely meet the legal discharge limits with a lot of additional equipment and operating effort, the Clearcat condensation stage is impressive in terms of the quality of the treated industrial wastewater. Even the strictest environmental standards are reliably met.

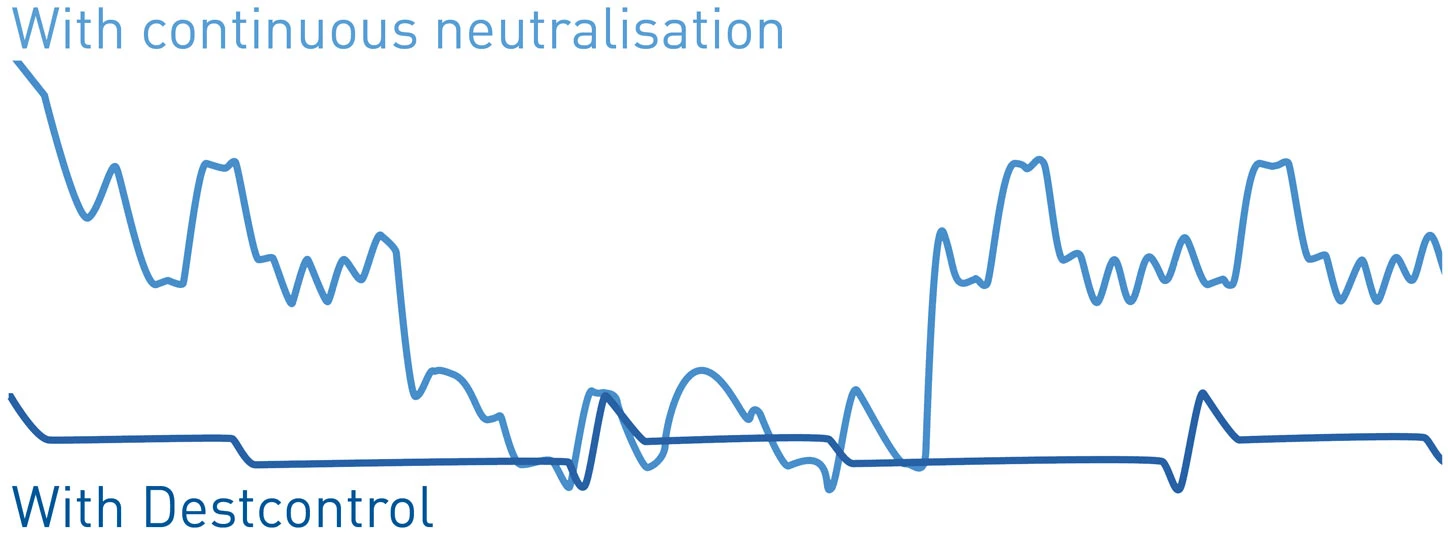

Comparison of pH value fluctuations in the distillate: Destcontrol reliably achieves stable values.

With Destcontrol, fluctuations in the pH value are a thing of the past. This innovative technology regulates the pH value in the purified distillate to the optimal value.

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com