Contact us

The more profitable a project, the greater the investment. But it’s not just high savings potentials which motivate businesses to invest in wastewater treatment. The responsibility to protect the environment is also playing a key role for an increasing number of industrial companies. That’s why thermofin’s main aim was to create a wastewater treatment system which enables sustainable recirculation and pays off quickly. A requirement which H2O GmbH from Steinen in Baden-Württemberg has fulfilled with its VACUDEST XS 360 vacuum distillation system.

The first contact between heat-exchanger manufacturer thermofin, based in the Saxon town of Reichenbach, and H2O GmbH, from Steinen in Baden-Württemberg, was made at the Pulversymposium in Dresden. Even at this early stage, it became clear that, with disposal costs of up to 1515 dollars per 1,000 gal (us.) of wastewater, a lot of money could be saved through wastewater treatment.

Thermofin specializes in manufacturing industrial heat exchangers, which are produced as per customer requirements in lengths of up to 26 feet. The reputable company’s customers include the Electoral Palace in Dresden, the Saudi Electricity Company in Riyadh, the Hamberger gastronomy wholesaler in Munich and the SnowDome indoor skiing facility in Bispingen (Lüneburg Heath). Thermofin’s heat-exchanger manufacturing processes result in stainless-steel pickling solutions, as well as rinse water from powder-coating pre-treatments. Around 0.08 million gallons of wastewater are produced each year.

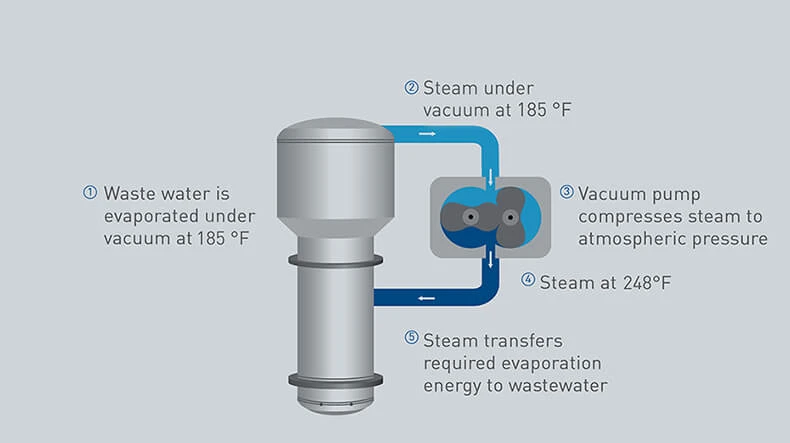

95 % energy recycling ensures cost effectiveness.

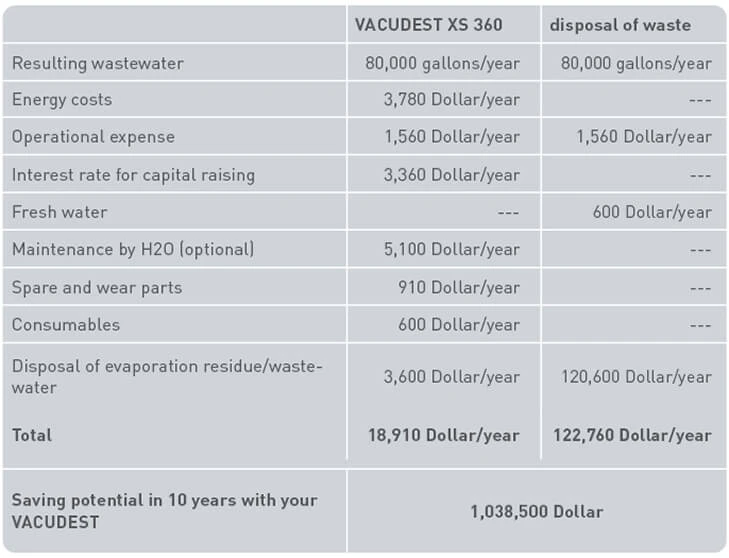

This wastewater from the stainless-steel pickling solution and the rinse water from the paint pre-treatment has previously been collected by a local disposal company and charged at a rate of up to 1,515 dollars per 1,000 gal. (us), resulting in additional production costs of over 100,000 dollars a year. The laboratory trial conducted at H2O’s application center for wastewater-free production found that wastewater quantities can be reduced by up to 98 percent. This 98 % saving in disposal costs means the investment’s profitability quickly becomes apparent.

The profitability calculation is impressive: in 10 years of operation, thermofin will save over 1 million dollars

with its VACUDEST.

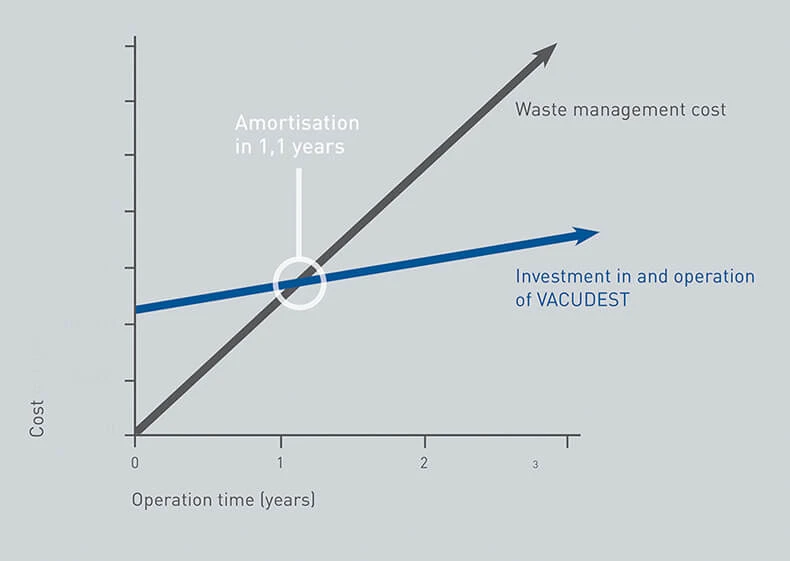

The graph shows how fast the investment in VACUDEST XS 360 will pay off for thermofin: just 1.1 years.

After production manager Thomas Speck expressed interest in seeing an H2O system in use at a customer facility, a visit was made to the production plant of Kaeser Kompressoren in Gera in April. He was thrilled with the clear structure, component layout and positive feedback from production managers: “Clean treatment like this would also work well at thermofin!”. He was particularly impressed by Kaeser’s ratings of the system’s profitability and reliability, and the results in terms of treatment and distillate quality. The system yields the exact results promised in the laboratory trial – which is very crucial when it comes to reusing the distillate.

The plan for treating and reusing the process water at the production plant was efficiently formulated, allowing both companies to meet for contract negotiations as early as May.

Tight spaces are not a problem for H2O GmbH’s engineers: The tanks were quickly placed on top of one another

to save space in the production facility.

The components and system were efficiently installed in August, thanks to H2O’s excellent planning. The tight space behind the powder coating area of the production plant posed a setup challenge; the VACUDEST XS 360, including tanks and residual oil separators, had to be installed in an area of just 10.8 x 13.1 feet. As space was tight on the side, a vertical layout was opted for, resulting in both tanks for neutralisation and distillate being placed on top of one another. The space provided was maximized. The production managers’ great interest in completing the project as quickly as possible also helped. Production manager Thomas Speck was always open to H2O’s queries and able to assist.

Thermofin has been saving on disposal costs for production wastewater since early September. The initial results have been very promising, and even managing director Bernd Löffler is pleased: “Thanks to VACUDEST, we are saving so much wastewater every day that the investment will soon pay itself off. We are delighted that the product could be carried out so quickly and smoothly, and that we can also help protect the environment.”

You have questions on our VACUDEST systems?

Kindly contact us!

Your contact is:

Thomas Dotterweich

Senior Sales Engineer

+49 7627 9239-306

thomasm.dotterweich@h2o-de.com

You need consumables, spare parts or a maintenance date?

We will be pleased to assist you!

Your contact is:

Carles Fité

Technical Customer Support

+49 7627 9239-888

carles.fite@h2o-de.com

You want to be part of our team and create the wastewater-free future with us?

We will tell you how!

Your contact is:

Bettina Böhringer

Human Resources

+49 7627 9239-201

career@h2o-de.com